Contents

Choosing between NMC and LiFePO4 batteries depends on your priorities. NMC batteries deliver higher energy density, offering superior performance for applications needing acceleration or extended range. LiFePO4 batteries excel in safety, resisting overheating and minimizing fire risks. Understanding these distinctions ensures you select a battery that aligns with your industrial requirements.

Key Takeaways

NMC batteries store more energy in less space. This makes them great for electric cars needing small size and long range.

LiFePO4 batteries are safer and last longer. They have a lower chance of overheating, making them good for medical tools and energy storage.

Pick the right battery based on your needs. Choose NMC for better performance and LiFePO4 for safety and saving money.

Part 1: Overview of NMC and LiFePO4 Batteries

1.1 NMC Battery Chemistry and Characteristics

NMC batteries, short for Nickel Manganese Cobalt batteries, rely on a layered oxide structure composed of nickel, manganese, and cobalt. This chemistry offers a high energy density, typically ranging from 160 to 270 Wh/kg, with a platform voltage of 3.6–3.7V. These batteries are widely used in applications requiring compact designs and extended runtime, such as electric vehicles (EVs), consumer electronics, and robotics. Research studies, including those analyzing over 3 billion data points from commercial cells, highlight NMC’s performance in terms of capacity retention and impedance fade. This data enables manufacturers to optimize operating strategies and predict battery degradation effectively.

1.2 LiFePO4 Battery Chemistry and Characteristics

LiFePO4 batteries, also known as Lithium Iron Phosphate batteries, feature a cathode material composed of lithium iron phosphate.LiFePO4 batteries prioritize safety and longevity, offering cycle lives between 2000 and 5000 cycles. Their thermal stability makes them ideal for energy storage systems, medical devices, and infrastructure applications. The growing adoption of LiFePO4 batteries reflects their cost-effectiveness and environmental benefits, with market share increasing to 39% in 2024.

Key Performance Parameters:

Theoretical discharge capacity: 170 mAh/g

Operating potential: 3.2 V vs Li+/Li

Typical LiFePO4 content in cathodes: 80–85 wt%

1.3 Advantages of NMC Batteries

NMC batteries excel in delivering high energy density, making them suitable for applications requiring lightweight designs and extended range. Their compact size supports industries like robotics and consumer electronics, where space constraints are critical. Additionally, NMC batteries dominate the EV market due to their ability to provide rapid acceleration and long driving ranges.

1.4 Advantages of LiFePO4 Batteries

LiFePO4 batteries offer unmatched safety and longevity. Their resistance to thermal runaway minimizes fire risks, making them ideal for security systems and medical devices. The lower cost of LiFePO4 batteries, approximately 30% cheaper than NMC batteries, further enhances their appeal for industrial applications and energy storage systems.

1.5 Limitations of NMC and LiFePO4 Batteries

Both battery types have distinct limitations. NMC batteries, despite their high energy density, face challenges with shorter cycle life and higher thermal runaway risks. For instance, modern 3Ah NMC cells drop to 60% capacity after 1000 cycles. On the other hand, LiFePO4 batteries have lower energy density, ranging from 100 to 180 Wh/kg, which limits their use in applications requiring compact designs.

Battery Type | Energy Density | Cycle Life | Safety | Thermal Runaway Risk |

|---|---|---|---|---|

LiFePO4 | Lower | Longer | Safer | Lower |

NMC | Higher | Shorter | Less Safe | Higher |

Part 2: Comparison Between NMC and LiFePO4 Batteries

2.1 Energy Density and Weight: NMC vs LiFePO4

Energy density plays a critical role in determining the suitability of a battery for specific applications. NMC batteries, with their nickel manganese cobalt chemistry, offer a significantly higher energy density compared to LiFePO4 batteries. This makes them ideal for applications like electric vehicles, where compact designs and extended range are essential.

The higher energy density of NMC batteries allows for lighter and smaller battery packs, which is advantageous in industries like robotics and consumer electronics. However, LiFePO4 batteries, despite their lower energy density, excel in weight stability and durability, making them suitable for stationary energy storage systems and industrial applications.

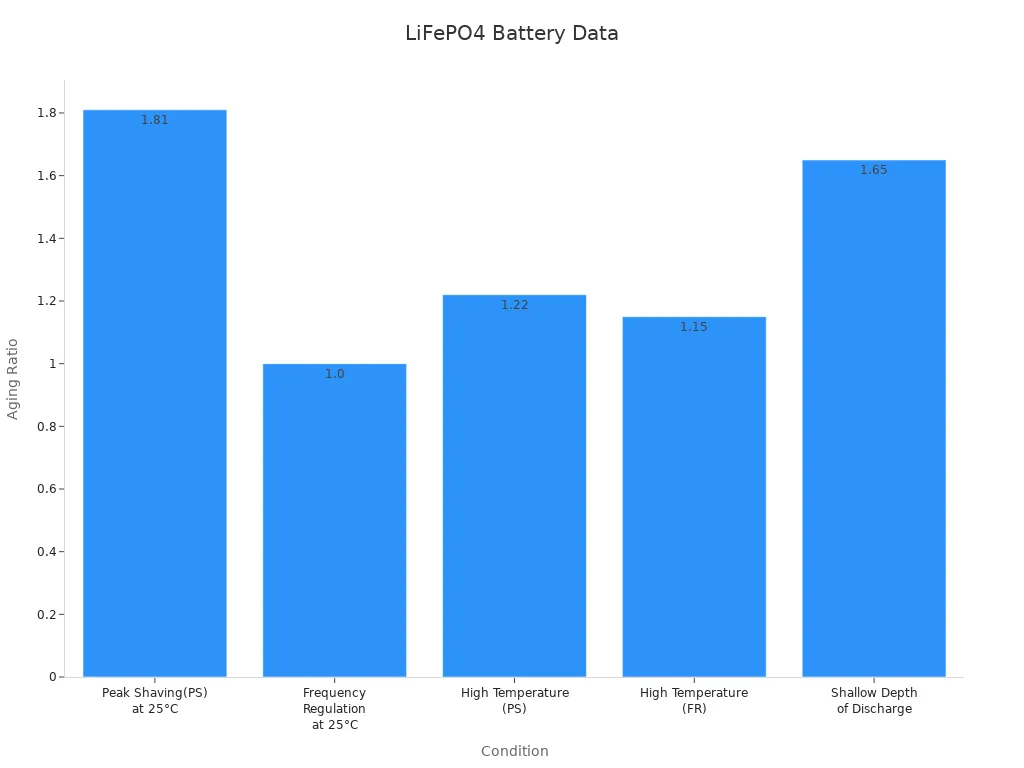

2.2 Cycle Life and Longevity: Comparison of LiFePO4 vs NMC Batteries

When it comes to longevity, LiFePO4 batteries outperform NMC batteries. Studies show that LiFePO4 batteries can achieve up to 5000 cycles, while NMC batteries typically last around 2000 cycles. This difference makes LiFePO4 batteries more cost-effective over time, especially for applications requiring frequent charging and discharging, such as medical devices and infrastructure systems.

A 2020 study in the Journal of the Electrochemical Society highlights that LiFePO4 batteries degrade at a much slower rate than NMC batteries.

Graphical data from the study reveals that NMC batteries lose capacity almost twice as quickly as LiFePO4 batteries under similar conditions.

The longer cycle life of LiFePO4 batteries ensures consistent performance over extended periods, reducing the need for frequent replacements and maintenance.

2.3 Safety and Thermal Stability: LiFePO4 vs. NMC Battery

Safety is a paramount concern in battery selection, and LiFePO4 batteries offer extraordinary safety compared to NMC batteries. Their inherent safety features, such as resistance to thermal runaway, make them a preferred choice for security systems and medical applications.

LiFePO4 batteries demonstrate better safety performance, with a lower risk of overheating or fire.

Research indicates that overcharging can lead to thermal runaway in both battery types, but LiFePO4 batteries are less prone to catastrophic failure.

Models developed for LiFePO4 batteries accurately simulate thermal runaway characteristics, with prediction errors of less than 3%.

NMC batteries, while offering higher energy density, have a less stable safety profile. They are more susceptible to overheating, especially under high-stress conditions. This makes them less suitable for applications where safety considerations are critical.

2.4 Cost and Material Availability

Cost and material availability significantly influence the choice between NMC and LiFePO4 batteries. NMC batteries are generally more expensive due to the use of cobalt, a material associated with high mining costs and ethical concerns.

Cell Format | Chemistry | Full Cost ($/kWh) | Levelized Cost ($/kWh) | Marginal Cost ($/kWh) |

|---|---|---|---|---|

Format A | NMC811 | 87 | 90 | 92 |

Format A | LiFePO4 | 91 | 94 | 96 |

Format B | NMC811 | 85 | 88 | 90 |

Format B | LiFePO4 | 89 | 92 | 94 |

LiFePO4 batteries, on the other hand, are more cost-effective over their lifespan. They do not rely on cobalt, making them more sustainable and affordable for large-scale energy storage and industrial applications.

2.5 Environmental Impact and Sustainability

The environmental impact of battery production and disposal is a growing concern. NMC batteries face criticism due to the environmental and ethical issues associated with cobalt mining. This has led to increased scrutiny and efforts to develop more sustainable alternatives.

LiFePO4 batteries, with their eco-friendly composition, offer a more sustainable solution. They do not contain cobalt or other conflict minerals, reducing their environmental footprint. Additionally, their longer cycle life minimizes waste, making them a greener choice for energy storage and industrial applications.

For more information on sustainability in battery production, visit Sustainability at Large Power.

Part 3: Choosing Between NMC and LiFePO4 Batteries

3.1 Evaluating Application-Specific Needs

Selecting the right battery depends on your application’s unique requirements. For high-energy-demand applications like robotics, NMC batteries provide superior energy density and compact designs. Their ability to deliver high power output makes them ideal for industries prioritizing performance and space efficiency. On the other hand, LiFePO4 batteries excel in applications requiring safety and longevity, such as medical devices, security systems, and infrastructure projects.

Metric | Description |

|---|---|

Voltage (V) | Indicates charge level and operational readiness. |

Capacity (Ah or Wh) | Total energy a battery can store and deliver; decreases over time due to aging. |

Internal Resistance | Affects efficiency and overheating; critical for high-power applications. |

State of Charge (SoC) | Represents remaining energy as a percentage; essential for battery management systems. |

State of Health (SoH) | Measures overall condition compared to original specs; key for replacement decisions. |

Cycle Life | Tracks number of charge-discharge cycles before performance decline. |

Temperature Sensitivity | Affects performance and longevity; important for extreme conditions in various applications. |

Understanding these metrics helps you align battery performance with operational goals, ensuring optimal results for your industry.

3.2 Budget and Cost Considerations

Budget constraints often influence battery selection. LiFePO4 batteries, with their lower cost and longer lifespan, offer a cost-effective solution for energy storage and industrial applications. Government subsidies, such as the U.S. Inflation Reduction Act, further enhance their affordability by providing tax credits of $35/kWh for cells and $10/kWh for modules. Additionally, advancements in manufacturing techniques are expected to reduce production costs by 10–15% over the next decade.

Key cost insights:

LiFePO4 batteries have a lower energy density (100–180 Wh/kg) compared to NMC batteries (160–270 Wh/kg).

Subsidies in the U.S., EU, and China promote the economic viability of LiFePO4 batteries.

NMC batteries remain more expensive due to the high cost of cobalt and nickel.

For applications requiring frequent replacements, the long-term cost benefits of LiFePO4 batteries outweigh their initial investment.

3.3 Safety and Compliance Requirements

Safety considerations are critical when choosing between NMC and LiFePO4 batteries. LiFePO4 batteries offer superior thermal stability, making them a safer choice for medical devices and security systems. They comply with rigorous safety standards, including UL and IEC certifications, ensuring reliable performance under various conditions.

Safety Standard/Testing Protocol | Description |

|---|---|

UL Certification | Ensures batteries meet safety standards to prevent overheating and short circuits. |

IEC Certification | International standard for safety and performance of batteries. |

CE Certification | Indicates compliance with health, safety, and environmental protection standards. |

Overcharge Tests | Tests to ensure batteries do not fail under excessive charging. |

Short Circuit Tests | Verifies battery safety in case of a short circuit. |

Environmental Temperature Tests | Ensures batteries operate safely under various temperature conditions. |

NMC batteries, while offering higher energy density, require additional safety measures to mitigate risks like thermal runaway. Evaluating compliance records and safety certifications ensures your battery choice aligns with industry standards.

3.4 Long-Term Performance and Maintenance

Long-term performance is a decisive factor in battery selection. LiFePO4 batteries, with a cycle life of 2000–5000 cycles, outperform NMC batteries, which typically last 1000–2000 cycles. This longevity reduces maintenance costs and minimizes downtime, making LiFePO4 batteries ideal for infrastructure and energy storage systems.

NMC batteries, despite their shorter lifespan, deliver consistent performance in high-energy-demand applications. Regular monitoring of metrics like capacity, state of charge, and state of health ensures optimal performance. Advanced battery management systems can further extend the lifespan of both battery types, providing a reliable solution for your operational needs.

For tailored battery solutions that meet your specific requirements, explore custom battery solutions.

Understanding the differences between NMC and LiFePO4 batteries helps you make informed decisions for your applications. NMC batteries, with their high energy density, are ideal for electric vehicles and portable electronics. LiFePO4 batteries, known for safety and longevity, excel in energy storage and industrial systems.

FAQ

1. What makes lithium iron phosphate batteries safer than NMC batteries?

LiFePO4 batteries resist thermal runaway and overheating. Their stable chemistry minimizes fire risks, making them ideal for safety-critical applications like medical devices and energy storage systems.

2. Are NMC batteries better for electric vehicles?

Yes, NMC batteries offer higher energy density. This allows for lighter battery packs and longer driving ranges, which are essential for electric vehicle performance.

3. How do LiFePO4 batteries compare in terms of environmental impact?

LiFePO4 batteries are more eco-friendly. They avoid cobalt and other conflict minerals, reducing their environmental footprint and promoting sustainable energy solutions.

For tailored solutions, explore custom battery solutions from Large Power.