Contents

The demand for lithium battery packs continues to surge across industries.

The automotive sector leads as the fastest-growing application for lithium ion batteries.

Energy storage systems, such as residential solar PV setups, are seeing rapid adoption.

Consumer electronics, accounting for over 31% of the market, showcase strong growth fueled by portable devices.

Building your own battery pack offers unmatched customization and cost efficiency. Advanced technologies like CTP can reduce production costs by up to 15% while increasing energy density by 20%. These benefits make it an attractive option for hobbyists and professionals alike. With proper guidance, assembling a lithium battery pack becomes both achievable and rewarding.

Key Takeaways

Knowing how lithium battery packs are built is very important.

Sorting and planning battery cells well makes them work better.

Adding a Battery Management System (BMS) keeps them safe and cool.

Part 1: Understanding Lithium Battery Packs

1.1 What Is a Lithium Battery Pack?

A lithium battery pack is a collection of lithium rechargeable batteries configured to deliver the desired voltage and capacity for specific applications. These packs are widely used in industries such as renewable energy storage, electric vehicles, and consumer electronics. They play a critical role in powering devices and systems efficiently and reliably.

Lithium battery packs consist of multiple cells connected in series or parallel. Each cell contains a positive electrode (cathode), a negative electrode (anode), a separator, and an electrolyte. The cathode materials, such as nickel, cobalt, and manganese, significantly influence the pack’s performance and cost. The electrolyte facilitates the movement of lithium ions, enabling the charging and discharging process.

1.2 Key Components of a Lithium Battery Pack

A lithium battery pack comprises several critical components, each contributing to its functionality and safety:

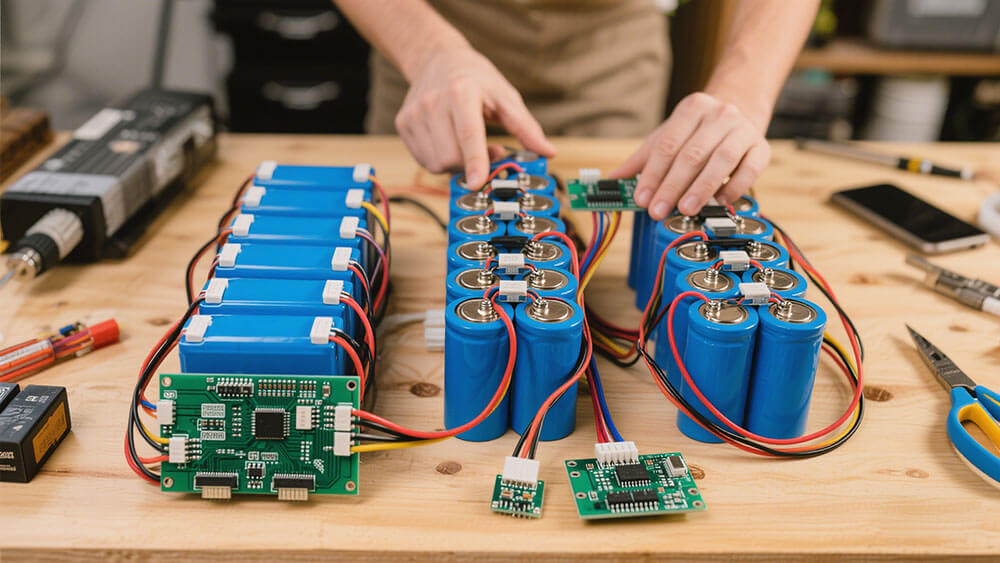

Battery Cells: The core of the pack, available in cylindrical (e.g., 18650, 21700) or prismatic formats.

Battery Management System (BMS): Monitors voltage, temperature, and current to ensure safe operation. It also prevents overcharging and over-discharging.

Thermal Management System: Maintains optimal operating temperatures using methods like air cooling, liquid cooling, or phase change materials.

Structural Components: Includes the casing and connectors, designed for durability and protection against environmental factors.

These components work together to deliver reliable power while ensuring safety and longevity. For more details on BMS operation, visit Battery Management System Operation & Components.

Part 2: Step-by-Step Guide to Assembling a Lithium Battery Pack

2.1 Planning the Battery Pack Design

Effective planning lays the foundation for a reliable lithium battery pack. You should start by defining the application requirements, such as voltage, capacity, and size constraints. A well-thought-out design ensures compatibility with your intended use and minimizes assembly errors.

Layout Planning: Sketch a detailed diagram of the battery pack layout, including cell arrangement and connections. This step helps visualize the series and parallel configurations.

Material Selection: Choose high-quality lithium rechargeable batteries, connectors, and insulation materials. Opt for components that meet your performance and safety standards.

Safety Guidelines: Incorporate safety measures, such as thermal management systems and protective casings, into your design.

Tip: Use technical diagrams to map out the installation of the battery management system (BMS) and thermal management components. This ensures balance in charge and discharge rates while preventing overheating.

2.2 Sorting and Preparing Battery Cells

Sorting battery cells is crucial for maintaining consistency and reliability in your lithium battery pack. You should group cells with similar voltage and capacity to ensure uniform performance.

Statistical studies highlight that aging properties of cells significantly influence the reliability of the battery system. Sorting methods that prioritize performance consistency are essential for applications requiring high reliability, such as energy storage systems.

Preparation Steps:

Measure the voltage and capacity of each cell using a battery analyzer.

Group cells with similar characteristics to prevent imbalances during operation.

Inspect cells for physical damage or defects before assembly.

Note: Proper sorting reduces the risk of weak cells affecting overall performance, especially in high-demand applications like industrial systems.

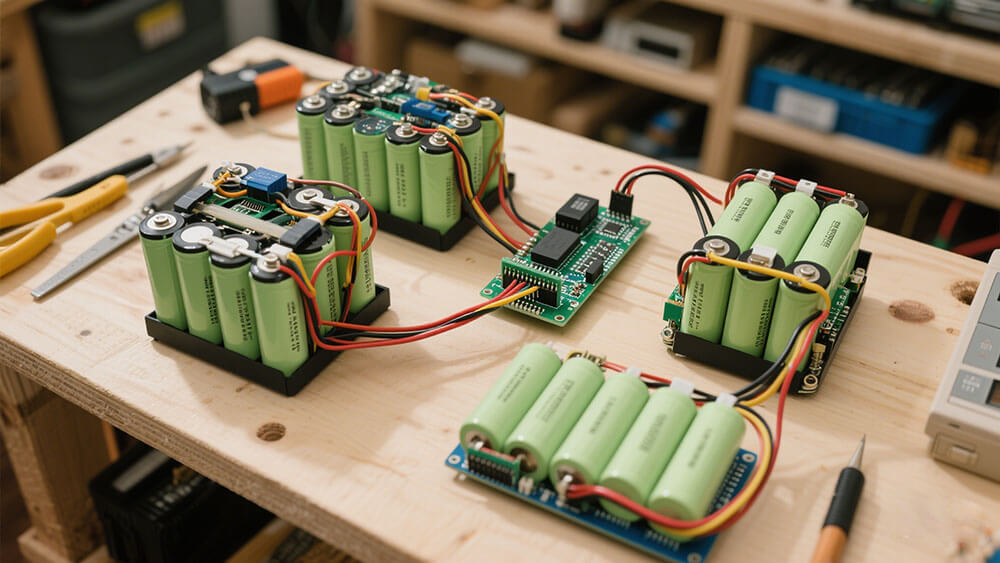

2.3 Connecting Cells: Series vs. Parallel Configurations

Choosing the right connection method depends on your application requirements. Series connections increase voltage, while parallel connections enhance capacity.

Series Connections:

Ideal for devices requiring higher voltages.

Weak cells in series can exhaust faster, affecting overall performance.

Parallel Connections:

Suitable for applications needing longer runtimes.

Weak cells reduce total load capability but are less critical than in series.

Tip: Match cells carefully in both configurations to prevent imbalances that could compromise safety and performance.

2.4 Integrating the Battery Management System (BMS)

The BMS is the brain of your lithium battery pack. It monitors voltage, temperature, and current to ensure safe operation. The Battery Management System (BMS) serves as the core control unit of a lithium battery pack. Its primary functions include real-time monitoring of critical parameters such as voltage, temperature, and current, dynamically regulating charging/discharging processes, implementing cell balancing management, and providing overcharge/over-discharge protection. It also delivers thermal runaway warnings, fault diagnostics, and precise estimations of State of Charge (SOC) and State of Health (SOH). By optimizing battery performance, extending service life, and ensuring system safety, the BMS facilitates secure data exchange with external devices (e.g., vehicle controllers or energy storage systems), thereby guaranteeing operational efficiency and safety in integrated applications.

2.5 Adding Thermal Management Systems

Maintaining optimal temperatures is critical for the longevity and performance of lithium battery packs. You can choose from various thermal management strategies based on your application.

Evidence Description | Findings |

|---|---|

Combination of PCM and liquid cooling | Reduces maximum temperature and controls temperature difference. |

Increased wind speed | Decreases operating temperature and temperature difference significantly. |

Coupled TMS with paraffin/expanded graphite | Enhances heat transfer performance, reducing operation time and energy consumption. |

Numerical simulations show that liquid cooling effectively addresses excessive temperature rise, especially during high discharge rates.

Recommended Strategies:

Combine PCM and liquid cooling for active heat dissipation.

Use wind cooling for cost-effective temperature control in low-power applications.

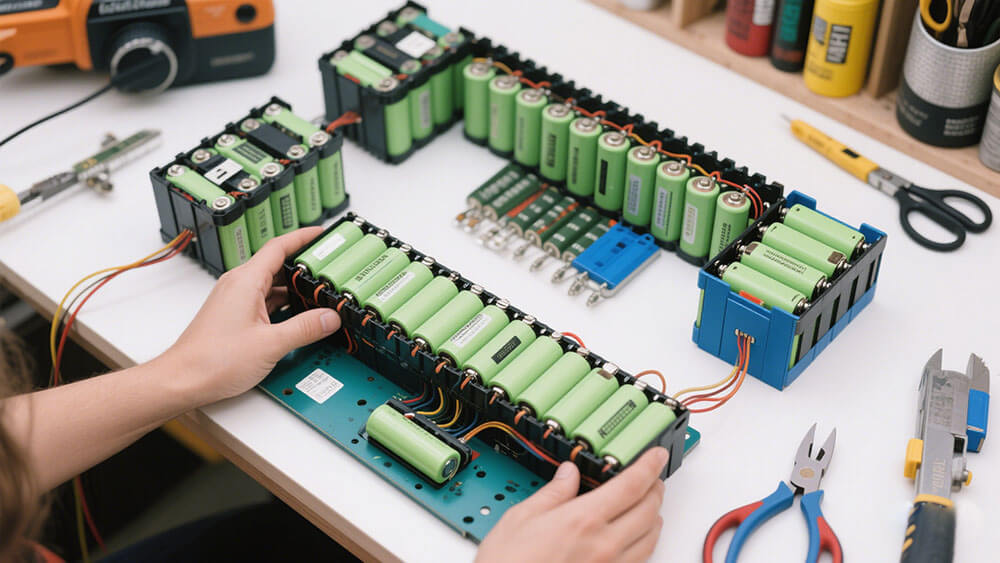

2.6 Securing, Insulating, and Sealing the Pack

Securing and insulating your battery pack protects it from environmental factors and mechanical stress. You should use durable structural components, such as aluminum casings or engineering plastics, to ensure long-term reliability.

Steps to Secure the Pack:

Fasten cells using brackets or adhesives to prevent movement.

Apply insulation materials to avoid electrical leakage.

Seal the pack with a protective casing to meet IP67/IP68 standards for water and dust resistance.

Tip: Prioritize lightweight materials with high strength and corrosion resistance for industrial applications.

2.7 Testing and Quality Assurance

Testing verifies the performance and safety of your lithium battery pack. You should conduct multiple tests to ensure reliability under various conditions.

Testing Method | Purpose |

|---|---|

Insulation Testing | Prevents electrical leakage and ensures safety. |

High-Voltage Testing | Verifies the battery’s ability to withstand voltage spikes. |

Resistance Testing | Measures internal and contact resistance affecting charging efficiency. |

Load Testing | Simulates real-world conditions to evaluate stability. |

Hall Effect Testing | Ensures accurate current measurements and verifies BMS functionality. |

Phase Loss Detection | Confirms all phases in multi-phase systems are connected and functioning properly. |

Note: Implementing these protocols minimizes defects and ensures compliance with industry standards.

Part 3: Safety Guidelines for Lithium Battery Pack Assembly

3.1 Avoiding Common Assembly Errors

Avoiding errors during assembly is critical to ensuring the safety and performance of your lithium battery pack. Even minor mistakes can lead to significant issues, such as reduced efficiency or safety hazards. Here are some common errors and how you can prevent them:

Improper Cell Matching: Using cells with mismatched capacities or voltages can cause imbalances, leading to overheating or reduced lifespan. Always sort and group cells with similar characteristics before assembly.

Inadequate Insulation: Failing to insulate connections properly can result in short circuits. Use high-quality insulation materials and double-check all connections.

Overtightened Connections: Excessive force when securing connections can damage cells or connectors. Tighten connections just enough to ensure stability without causing strain.

Neglecting Thermal Management: Ignoring heat dissipation can lead to thermal runaway. Incorporate a robust thermal management system, such as liquid cooling or phase change materials, to maintain safe operating temperatures.

Tip: Create a checklist of assembly steps and inspect each component thoroughly to minimize errors. This proactive approach ensures a high-quality battery pack that meets safety standards.

3.2 Safe Handling of Lithium Rechargeable Batteries

Handling lithium rechargeable batteries requires strict adherence to safety protocols. These batteries are sensitive to physical and electrical stress, making proper handling essential.

When handling batteries:

Inspect for Damage: Check for dents, leaks, or swelling before use. Damaged cells should never be included in your assembly.

Use Protective Gear: Wear gloves and safety goggles to protect yourself from potential chemical leaks or sparks.

Avoid Overcharging: Always charge batteries within the recommended voltage range to prevent overheating.

Note: Lowering the state of charge during storage or transport significantly reduces the risk of thermal runaway. This practice is especially important for large-scale industrial applications.

3.3 Preventing Electrical Hazards and Overheating

Electrical hazards and overheating are among the most significant risks when assembling lithium battery packs. You can mitigate these risks by following these best practices:

Install a Battery Management System (BMS): A BMS monitors voltage, current, and temperature, ensuring safe operation. It also prevents overcharging and over-discharging, which are common causes of overheating. Learn more about BMS functionality here.

Use Proper Wiring Techniques: Ensure all connections are secure and free from loose wires. Spot welding is often preferred over soldering for its reliability and precision.

Incorporate Thermal Management Systems: Use advanced cooling methods, such as liquid cooling or phase change materials, to dissipate heat effectively.

Tip: Regularly test your battery pack under simulated load conditions to identify and address potential overheating issues before deployment.

3.4 Proper Storage and Disposal Practices

Proper storage and disposal of lithium battery packs are essential for safety and environmental sustainability. Mishandling can lead to safety hazards or environmental damage.

Evidence Type | Description |

|---|---|

Recycling Capacity | Ganfeng Lithium’s recycling capacity has significantly increased from 2021 to 2023, indicating rising demand for lithium-ion cell recycling. |

Lithium Mining Statistics | Nearly 60% of lithium is currently mined for battery-related applications, projected to rise to 95% by 2030, highlighting the urgency for sustainable practices. |

Job Creation | The battery industry is projected to create up to 18 million jobs by 2030, driven by increased demand for batteries and related technologies. |

Storage Guidelines:

Store batteries in a cool, dry place away from direct sunlight or heat sources.

Maintain a partial state of charge (around 40-60%) for long-term storage to reduce degradation.

Use fireproof containers for added safety, especially for large battery packs.

Disposal Guidelines:

Recycle batteries through certified facilities to recover valuable materials like lithium and cobalt.

Avoid disposing of batteries in regular trash, as this can lead to environmental contamination.

Partner with organizations that specialize in battery recycling to ensure compliance with regulations.

Sustainability Note: Recycling lithium-ion batteries not only reduces environmental impact but also supports the growing demand for lithium battery technology. Learn more about sustainable practices at Large Power.

Assembling a lithium battery pack involves careful planning, precise execution, and adherence to safety protocols. You gain the ability to customize the pack for your specific needs while saving costs compared to pre-assembled options. Prioritize regular maintenance and safe handling to ensure long-term reliability and performance. Building a lithium battery pack can be both rewarding and practical when done responsibly.

FAQ

1. How do I choose the right lithium battery chemistry for my application?

Each chemistry offers unique benefits:

Chemistry | Voltage (V) | Energy Density (Wh/Kg) | Cycle Life (Cycles) | Best For |

|---|---|---|---|---|

LCO | 3.7 | 180-230 | 500-1000 | |

NMC | 3.5-3.6 | 160-270 | 1000-2000 | Electric vehicles, robotics |

LiFePO4 | 3.2 | 100-180 | 2000-5000 | Industrial, medical |

Tip: For long cycle life and safety, consider LiFePO4 Lithium batteries.

2. What is the role of a Battery Management System (BMS)?

A BMS ensures safe operation by monitoring voltage, current, and temperature. It prevents overcharging, over-discharging, and overheating. Learn more about BMS here.

3. Can I customize a lithium battery pack for specific industrial needs?

Yes, Large Power offers tailored solutions for industrial applications. Visit our custom battery solutions page to explore options.