Contents

Lithium serves as a cornerstone of modern technology, powering innovations in energy storage and transportation. Its unique physical states enable applications in industries ranging from electronics to automotive. Lithium-ion batteries, for example, experienced a compound annual growth rate of 24% between 2015 and 2018. Automotive applications alone accounted for 70% of lithium-ion battery shipments by 2018, underscoring lithium’s pivotal role in electric vehicles. Understanding lithium’s physical states and properties remains essential for optimizing its industrial use, particularly in battery technology.

Key Takeaways

Lithium is important for today’s technology, like batteries in electric cars. Its special traits help make light and durable batteries.

Knowing how lithium reacts and handling it safely is very important. Storing it correctly and following safety rules can stop battery accidents.

The need for lithium will rise as electric cars and green energy improve. Better ways to recycle and mine lithium will help use it responsibly.

Part 1: Overview of Lithium

1.1 Lithium’s Physical States and Classification

Lithium, the lightest of all metals, belongs to the group of alkali metals on the periodic table. It exhibits a silvery-white appearance and remains solid under standard conditions. As an alkali metal, lithium shares properties such as high reactivity and low density with its group counterparts. However, it stands out due to its exceptional electrochemical potential, making it indispensable in energy storage applications.

In its pure form, lithium is soft enough to be cut with a knife, yet it oxidizes rapidly when exposed to air. This reactivity necessitates careful handling and storage in inert environments. Its unique combination of physical and chemical properties has positioned lithium as a cornerstone material in modern technology.

1.2 Sources and Extraction Methods

Lithium is primarily sourced from two types of deposits: brine pools and hard rock minerals. Brine resources account for approximately 60% of global reserves but contribute only 35% to production. In contrast, hard rock mining, which represents 30% of reserves, supplies over 60% of global lithium production. This disparity highlights the untapped potential of brine resources, which could significantly enhance extraction efficiency in the future.

The global lithium mining market is projected to grow at a compound annual growth rate (CAGR) of 9.7% from 2025 to 2035. Innovations in extraction technologies, such as direct lithium extraction (DLE), aim to improve yield and reduce environmental impact. These advancements are critical for meeting the rising demand for lithium in energy storage systems.

1.3 Role of Lithium in Battery Technology

Lithium’s role in battery technology stems from its high energy density and electrochemical stability. These characteristics enable the production of lightweight, long-lasting batteries that power devices ranging from smartphones to electric vehicles.

Empirical studies have shown that lithium-ion batteries exhibit predictable degradation patterns, often analyzed using metrics like the State of Health (SOH). This metric helps manufacturers determine when a battery reaches its end of life, ensuring optimal performance and safety. Advances in lithium battery technology continue to drive innovation in renewable energy storage and electric mobility, solidifying lithium’s status as a critical material in the global energy transition.

Note: For more information on sustainable lithium practices, visit Sustainability at Large Power.

Part 2: Physical Properties of Lithium

2.1 Melting and Boiling Points

Lithium, known as the lightest solid metal, exhibits unique physical properties that distinguish it from other alkali metals. Its melting point is approximately 180.5°C (356.9°F), while its boiling point reaches 1,342°C (2,448°F). These values are significantly higher than those of other group members, such as sodium and potassium. This difference arises from lithium’s smaller atomic size and higher ionization energy, which contribute to a more robust metallic lattice structure.

Property | Lithium | Sodium | Potassium |

|---|---|---|---|

Melting Point (°C) | 180.5 | 97.8 | 63.5 |

Boiling Point (°C) | 1,342 | 883 | 759 |

Density (g/cm³) | 0.534 | 0.968 | 0.862 |

The higher melting and boiling points of lithium make it suitable for applications requiring thermal stability, such as in lithium-ion batteries. These properties ensure that lithium remains stable under the high temperatures generated during battery operation, enhancing safety and performance.

2.2 Thermal and Electrical Conductivity

Lithium’s thermal and electrical conductivity further solidify its role in modern technology. As the lightest solid metal, it demonstrates excellent thermal conductivity, measured at approximately 84.8 W/(m·K). This property allows lithium to dissipate heat efficiently, a critical factor in preventing overheating in lithium-ion batteries.

In terms of electrical conductivity, lithium’s low atomic mass and high specific heat capacity (3.58 J/g·K) enable it to transport electrical charges effectively. This characteristic is vital for the rapid charging and discharging cycles required in energy storage systems.

Key Advantages of Lithium’s Conductivity:

Efficient heat dissipation reduces the risk of thermal runaway in batteries.

High electrical conductivity supports faster energy transfer, improving battery performance.

These properties make lithium indispensable in the production of lightweight, high-capacity batteries for electric vehicles and portable electronics. Its ability to maintain stability under varying thermal and electrical conditions ensures reliability in demanding applications.

For industries seeking custom battery solutions tailored to specific needs, explore Custom Battery Solutions by Large Power.

Part 3: Chemical Properties of Lithium

3.1 Reactivity with Water and Air

Lithium exhibits high reactivity, a hallmark of its chemical properties. When exposed to air, it reacts with oxygen to form lithium oxide (Li₂O), which gives the metal a dull, tarnished appearance. This reaction occurs rapidly, necessitating storage in inert environments such as mineral oil or argon gas. Additionally, lithium reacts with nitrogen in the atmosphere to produce lithium nitride (Li₃N), a compound that forms a protective layer on the metal’s surface.

When lithium reacts with water, it produces lithium hydroxide (LiOH) and hydrogen gas (H₂). This reaction is highly exothermic, releasing significant heat. The equation for this reaction is:

2Li + 2H₂O → 2LiOH + H₂↑

The high reactivity of lithium with water underscores the need for stringent safety measures during handling and storage. In lithium-ion batteries, this property is carefully controlled to prevent unwanted reactions, ensuring operational safety and efficiency.

3.2 Formation of Lithium Compounds

Lithium’s ability to form a wide range of compounds is central to its industrial applications. It reacts with halogens, such as chlorine, to produce lithium halides like lithium chloride (LiCl). These compounds are highly soluble in water and play a crucial role in electrolyte formulations for lithium-ion batteries.

Lithium also reacts with hydrogen to form lithium hydride (LiH), a compound used in hydrogen storage and as a reducing agent in chemical synthesis. Additionally, lithium reacts with carbon dioxide to form lithium carbonate (Li2CO3), a key precursor in battery-grade cathode materials. The versatility of lithium compounds enables their use in diverse applications, from ceramics to pharmaceuticals.

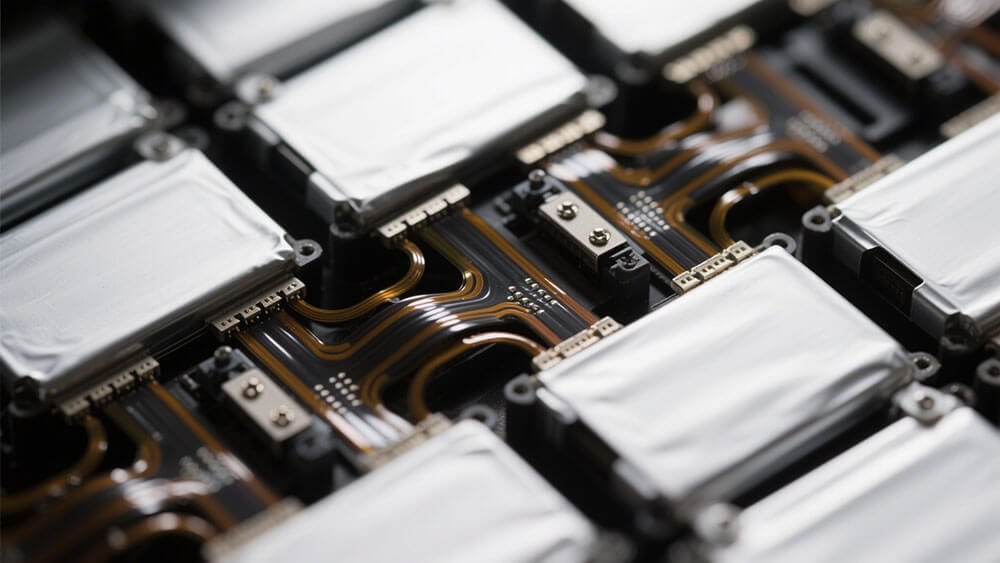

In the context of energy storage, lithium compounds like lithium cobalt oxide (LiCoO2) and lithium iron phosphate (LiFePO4) serve as active materials in battery cathodes. These compounds contribute to the high energy density and long cycle life of lithium-ion batteries, making them indispensable in renewable energy systems and electric vehicles.

3.3 Behavior in Electrochemical Reactions

Lithium’s behavior in electrochemical reactions defines its role in energy storage technology. Its low atomic mass and high electrochemical potential (-3.04 V relative to the standard hydrogen electrode) make it an ideal candidate for battery applications. During discharge, lithium ions migrate from the anode to the cathode through the electrolyte, releasing energy in the process. This reversible reaction enables repeated charging and discharging cycles, a critical feature of lithium-ion batteries.

The electrochemical properties of lithium also contribute to its high energy density. For instance, lithium-ion batteries can achieve energy densities of up to 250 Wh/kg, significantly outperforming other battery chemistries. This efficiency supports the growing demand for lightweight, high-capacity batteries in electric vehicles and portable electronics.

Note: For custom battery solutions tailored to specific industrial needs, explore Custom Battery Solutions by Large Power.

The chemical properties of lithium, including its high reactivity and ability to form diverse compounds, underpin its widespread use in modern technology. These characteristics not only enhance the performance of lithium-ion batteries but also drive innovation in energy storage systems.

Part 4: Practical Implications for Lithium Applications

4.1 Lithium’s Role in Battery Manufacturing

Lithium plays a pivotal role in the production of advanced batteries, particularly lithium-ion batteries. These batteries are renowned for their high energy density, long lifespan, and lightweight design, making them indispensable in industries such as automotive, electronics, and renewable energy. Lithium-ion batteries minimize energy loss during operation, reducing overall energy consumption in manufacturing facilities. Their efficiency also supports cost savings by lowering operational expenses and extending product lifespans.

In addition to economic benefits, lithium-ion batteries contribute to sustainability. They enable the integration of renewable energy sources and reduce carbon emissions, aligning with global efforts to combat climate change. For instance, lithium iron phosphate (LiFePO4) batteries have revolutionized energy solutions in the oil and gas sector. Unlike traditional lead-acid batteries, LiFePO4 batteries offer reliable performance in harsh environments, minimizing downtime and equipment failures.

4.2 Challenges in Handling and Safety

Despite its advantages, lithium presents significant challenges in handling and safety. Its high reactivity with air and water increases the risk of incidents, particularly in applications involving rechargeable devices. Over the past five years, thermal runaway incidents involving lithium batteries have risen by 28%, with an average of two cases reported weekly. Most incidents occur in confined spaces, such as aircraft cabins, where passengers often carry multiple rechargeable devices.

Statistic | Description |

|---|---|

Incidents | |

Devices | E-cigarettes caused 35% of incidents in 2023. |

Prevention Success Rate | 85% of incidents addressed before escalating to fire or explosion stages. |

To mitigate these risks, industries must adopt stringent safety protocols. Proper storage, regular inspections, and the use of advanced battery management systems can significantly reduce the likelihood of accidents.

4.3 Future Opportunities in Lithium Applications

The demand for lithium is expected to grow exponentially in the coming decades, driven by advancements in electric vehicles (EVs) and renewable energy systems. The International Energy Agency (IEA) predicts that by 2030, there will be 125 million EVs on the road, with EVs comprising 90% of the global fleet by 2050. This surge will significantly increase the need for lithium-ion batteries.

Application Area | Forecast Details |

|---|---|

Electric Vehicles | 125 million EVs by 2030; 90% of global fleet by 2050. |

Renewable Energy | Six-fold growth in renewable capacity by 2050, requiring more lithium-ion batteries. |

Energy Storage Systems | Global energy storage market projected to exceed 2,500 GW by 2050. |

Additionally, innovations in lithium recycling and extraction technologies will play a crucial role in meeting future demand. Companies are exploring methods to improve lithium recovery rates while minimizing environmental impact. These advancements will ensure a sustainable supply chain, supporting the transition to a low-carbon economy. For custom battery solutions tailored to specific industrial needs, explore Custom Battery Solutions by Large Power.

Lithium’s unique physical and chemical properties, such as high energy density and thermal stability, make it indispensable across industries. Its role in electric vehicles, electronics, and renewable energy storage underscores its significance.

Application Area | Significance |

|---|---|

Automotive | Essential for electric vehicle battery production, driven by the shift towards sustainable transport. |

Electronics | Key component in lithium-ion batteries for portable devices, reflecting demand for efficiency. |

Energy Storage | Critical for storing renewable energy, supporting the transition to sustainable energy solutions. |

Ongoing research into lithium recycling and extraction technologies will ensure its sustainable use in future applications.

FAQ

1. What makes lithium ideal for battery manufacturing?

Lithium’s high energy density, lightweight nature, and electrochemical stability make it essential for producing efficient and long-lasting batteries.

Tip: Learn more about custom lithium battery solutions at Large Power.

2. How does lithium-ion battery recycling impact sustainability?

Recycling reduces waste and conserves resources by recovering valuable materials like lithium and cobalt. This supports sustainable practices in energy storage systems.

Note: Explore sustainable lithium practices at Sustainability at Large Power.

3. Why is safety critical when handling lithium?

Lithium’s high reactivity with air and water increases risks of thermal runaway and fire. Proper storage and advanced battery management systems ensure safety.