Contents

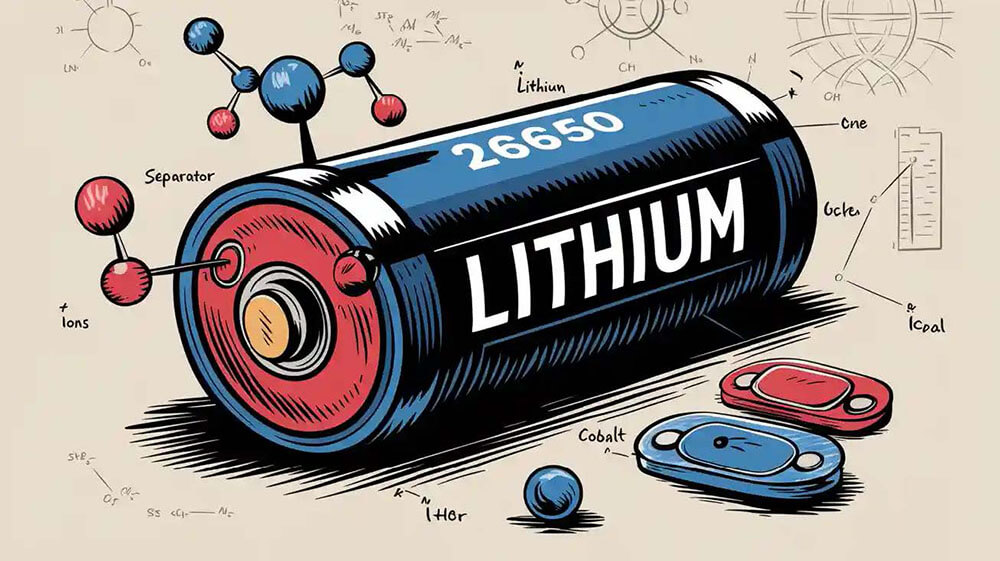

26650 lithium batteries, recognized for their cylindrical design and high capacity, are essential components in modern energy storage systems. The chemistry of 26650 lithium batteries, combined with their robust structure, allows for efficient power delivery, making them vital in industries such as medical, robotics, and industrial.

The global market for 26650 lithium-ion batteries is anticipated to grow at a compound annual growth rate (CAGR) of 15% over the next five years, fueled by the rising demand for energy-efficient solutions in infrastructure and consumer electronics.

A deeper understanding of the chemistry of 26650 lithium batteries is key to optimizing their performance, improving safety, and advancing sustainable applications.

Key Takeaways

26650 lithium batteries are important for medical tools, robots, and energy storage because they store a lot of power and work well.

Picking the right cathode material, like LiFePO4 or NMC, changes how much energy the battery holds, how long it lasts, and how safe it is. This is very important for certain uses.

The parts inside, like the anode, electrolyte, and separator, help the battery work better, stay safe, and last longer.

Part 1: Chemistry of 26650 Lithium Battery

1.1 Cathode Materials and Their Variants

The cathode plays a pivotal role in the performance of a lithium-ion battery. In 26650 cells, the cathode typically consists of materials like LiFePO4 (Lithium Iron Phosphate), NMC (Nickel Manganese Cobalt), or LCO (Lithium Cobalt Oxide). Each material offers distinct advantages.

LiFePO₄

Characteristics: High safety (excellent thermal stability), long cycle life (up to 5,000 cycles), low cost, but lower energy density (nominal voltage: 3.2V, capacity: ~3,000-3,500mAh).

Applications: Ideal for high-safety and long-life scenarios like power tools and energy storage systems.

NMC

Characteristics: High energy density (nominal voltage: 3.7V, capacity up to 5,000-7,000mAh), but lower safety and cycle life compared to LiFePO₄.

Applications: High-power devices requiring instantaneous high-current discharge, such as drones and power tools.

LCO

Characteristics: High specific capacity but costly and thermally unstable. Rarely used in 26650 batteries, more common in consumer electronics.

1.2 Anode Composition and Function

The anode in a 26650 lithium-ion battery is typically made of graphite, a material known for its high conductivity and ability to store lithium ions. During the charging process, lithium ions migrate from the cathode to the anode, where they are stored in the graphite’s layered structure. This process is reversed during discharge, enabling the battery to deliver power.

Graphite anodes are favored for their stability and efficiency. However, advancements in anode materials, such as silicon-graphite composites, are being explored to enhance the energy density of lithium-ion cells. These innovations aim to meet the growing demand for high-performance rechargeable batteries in sectors like robotics and security systems.

Part 2:Performance Implications of Cathode Materials of 26650: LiFePO4 vs. NMC

2.1 Energy Density and Power Output

The energy density and power output of a lithium-ion battery depend heavily on its chemical composition and structural design. In 26650 cells, cathode materials like NMC and LiFePO4 influence energy density, which ranges from 100 to 270 Wh/kg depending on the chemistry. NMC Lithium batteries, with their higher energy density, are ideal for consumer electronics applications requiring compact designs and prolonged usage. LiFePO4 Lithium batteries, while offering lower energy density, excel in industrial applications due to their durability and safety.

Power output is another critical factor. The electrolyte and separator materials in 26650 cells ensure efficient ion transport, enabling rapid discharge rates. This characteristic makes these cells suitable for robotics and security systems, where consistent and high power delivery is essential.

Tip: Businesses seeking customized solutions for high-performance battery packs can explore tailored options through Large Power.

2.2 Thermal Stability and Safety Mechanisms

LiFePO₄:

Superior thermal stability, decomposing at ~270°C, reducing thermal runaway risks.

Performs well in abuse tests (overcharge, nail penetration) due to minimal oxygen release during overheating.

NMC:

Higher thermal runaway risk, decomposing at ~150°C, exacerbated by reactive Ni/Co content.

Requires advanced battery management systems (BMS) and ceramic-coated separators to mitigate safety issues.

Thermal stability is a defining feature of 26650 lithium-ion batteries. LiFePO4 Lithium batteries, known for their robust thermal properties, can withstand high temperatures without compromising performance.

2.3 Lifespan and Charge-Discharge Cycles

The lifespan of a lithium-ion battery is determined by its charge-discharge cycle capacity. LiFePO4 Lithium batteries lead the industry with up to 5,000 cycles, making them a preferred choice for industrial and infrastructure projects requiring long-term reliability. NMC Lithium batteries offer 1,000 to 2,000 cycles, balancing energy density and durability for consumer electronics and robotics applications.

Note: Proper maintenance and usage conditions can significantly extend the lifespan of rechargeable batteries, ensuring optimal performance over time.

The structural integrity of 26650 cells also plays a role in their longevity. High-quality separators and electrolytes minimize degradation, preserving the battery’s capacity and efficiency. Businesses can explore customized battery solutions to meet specific lifespan requirements through Large Power.

Part 3: Applications of 26650 Lithium Batteries in Battery Packs

3.1 Use in Industrial Energy Storage Systems

26650 lithium-ion batteries play a crucial role in industrial energy storage systems. Their high energy density and long cycle life make them ideal for applications requiring reliable and sustainable power solutions. For example, LiFePO4 cells, known for their thermal stability and durability, are widely used in infrastructure projects such as transportation and renewable energy storage. These batteries can endure up to 5,000 charge-discharge cycles, ensuring long-term performance in demanding environments.

The robust structure of 26650 cells allows them to withstand harsh conditions, including extreme temperatures and mechanical stress. This makes them suitable for industrial machinery and grid-level energy storage systems. Additionally, their ability to deliver consistent power output ensures uninterrupted operation in critical applications. Businesses seeking customized battery solutions for industrial use can benefit from tailored designs that optimize performance and safety. Learn more about custom battery solutions.

3.2 Applications in High-Performance Devices

High-performance devices, such as robotics, medical equipment, and security systems, rely on the efficiency and reliability of 26650 lithium-ion batteries. These cells provide the high power output required for rapid and precise operations in robotics.

In medical devices, the compact design and high energy density of 26650 cells ensure portability and extended usage. For instance, LCO cells, with an energy density of 180–230 Wh/kg, are often used in lightweight medical equipment.

Security systems also benefit from the reliability of these batteries. Advanced separators and solid-state electrolytes enhance safety, reducing the risk of thermal runaway. This ensures consistent performance in surveillance and emergency response systems.

Tip: Businesses can explore customized battery packs for high-performance devices through Large Power.

The chemical composition and structural design of 26650 lithium-ion batteries play a pivotal role in their performance and application versatility. Materials like LiFePO4 and NMC enhance energy density, thermal stability, and lifespan, making these cells suitable for diverse industries, including infrastructure and consumer electronics. The global market for these batteries is projected to grow at a CAGR of 6.57%, reaching USD 3.2 billion by 2032, driven by their adoption in electric vehicles and industrial machinery. Businesses should prioritize these factors to ensure optimal battery performance and safety. For tailored solutions, consult Large Power.

FAQ

1. What makes 26650 lithium-ion batteries suitable for industrial applications?

26650 lithium-ion batteries offer high energy density, long cycle life, and thermal stability, making them ideal for industrial systems requiring reliable and sustainable power.

2. How do 26650 batteries enhance safety in medical devices?

Advanced separators and solid-state electrolytes in 26650 batteries reduce thermal runaway risks, ensuring safety in critical medical applications.

3. Can businesses customize 26650 battery packs for specific needs?

Yes, businesses can design tailored 26650 battery packs to optimize performance and safety for unique applications. Consult Large Power for custom solutions.