Contents

LCO batteries, also known as lithium cobalt oxide batteries, are a cornerstone of the lithium-ion battery ecosystem. These batteries stand out due to their high specific capacity and stable structure, making them indispensable in high-energy-density applications. In 2025, their role becomes even more critical, especially in consumer electronics, where compact designs and efficient energy storage are paramount. Their ability to deliver consistent power over extended periods ensures their relevance in portable devices and emerging technologies. Market projections indicate steady growth in LCO battery applications, driven by advancements in portable electronics and medical devices.

To explore custom battery solutions tailored to your business needs, visit Large Power.

Key Takeaways

LCO batteries are important for small gadgets. They store a lot of energy and are small, perfect for phones and laptops.

Safety is very important for LCO batteries. Makers add safety features to stop overheating and keep them working well.

Using cobalt in LCO batteries makes them expensive and raises ethical issues. This leads companies to look for better, eco-friendly options.

Part 1: Anatomy and Characteristics of LCO Batteries

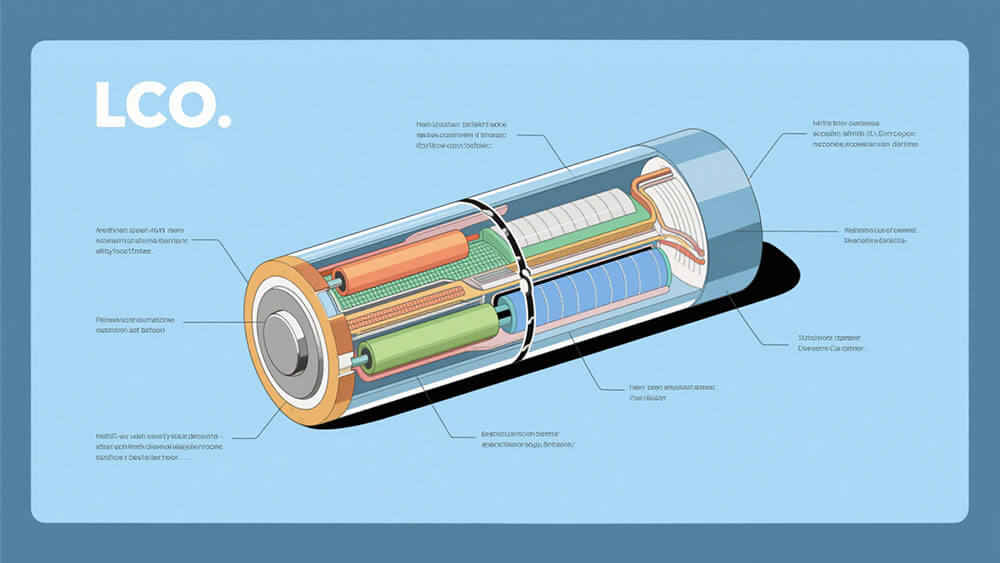

1.1 Composition and Structure of LCO Batteries

LCO batteries, or lithium cobalt oxide batteries, are built around a layered structure of cobalt oxide (LiCoO₂) as the cathode material. This composition enables high energy density and stable electrochemical performance. The cathode’s layered arrangement facilitates efficient lithium-ion movement during charge and discharge cycles, ensuring consistent energy delivery.

Modern advancements have increased the maximum voltage of LCO cells to 4.35V, enhancing their energy output. These batteries maintain a useful voltage above 3.6V even when the charge drops to 5%, making them ideal for mobile applications.

Key structural metrics include:

Point Defect Ratio: Indicates phase stability of electrode materials.

TM Layer Spacing: Determines lithium storage sites and electrochemical capacity.

These structural properties contribute to the reliability and efficiency of LCO batteries in consumer electronics.

Note: The cobalt dependency of LCO batteries raises sustainability concerns. Learn more about ethical sourcing in our Conflict Minerals Statement.

1.2 Key Performance Metrics of Lithium Batteries

Performance metrics define the capabilities of lithium batteries, including LCO batteries. These benchmarks include energy density, cycle life, and cost-effectiveness.

Performance Metric | Benchmark Value | Target Improvement |

|---|---|---|

Charge-Discharge Cycles | 500 cycles | Increase by 15-20% |

Capacity Retention | 80% after 500 cycles | Maintain or exceed 85% |

Total Cost of Ownership | Industry average reduction of 30% | Reduce costs by an additional 10% |

Key indicators for lithium batteries include:

Watt-hours: Measures energy delivery capacity.

Energy Density: Reflects the amount of energy relative to size.

Cycle Life: Indicates the number of charge-discharge cycles before capacity drops below 80%.

LCO batteries excel in energy density, with values ranging from 180 to 230 Wh/kg. Their platform voltage of 3.7V ensures stable energy output, making them suitable for high-performance applications.

1.3 Unique Features of LCO Batteries in Battery Packs

LCO batteries offer distinct advantages when integrated into battery packs. Their high energy density and compact design make them ideal for portable devices. The stable voltage platform simplifies battery pack configurations, reducing the need for complex series-parallel arrangements.

Attribute | LCO Battery | NMC Battery |

|---|---|---|

Energy Density | Slightly lower than NMC | Higher energy density |

Power Density | Lower power density | Good power density |

Cycle Life | Shorter cycle life | Longer cycle life |

Cost | More expensive due to cobalt content | Generally less expensive |

Thermal Stability | Less stable, prone to overheating | Better thermal stability |

Common Applications | Consumer electronics (smartphones) | Electric vehicles, energy storage |

The ability of LCO batteries to maintain consistent performance under varying conditions makes them indispensable for consumer electronics. Their compact design ensures seamless integration into devices like smartphones and laptops.

🔧 Pro Tip: For custom battery solutions tailored to your industrial needs, visit Large Power.

Part 2: Advantages and Limitations of LCO Batteries

2.1 High Energy Density and Compact Design

LCO batteries excel in applications where high energy density and compact design are critical. Their cathode material, lithium cobalt oxide (LiCoO₂), enables energy densities ranging from 180 to 230 Wh/kg, making them ideal for portable devices like smartphones and laptops. You benefit from their ability to store significant energy in a small footprint, which simplifies device design and reduces overall weight.

Studies confirm the practical advantages of LCO batteries in high-energy-density configurations. For instance, research shows that LCO cathodes achieve a specific capacity of approximately 190 mAh g−1 and maintain performance at high charge voltages (up to 4.55 V) across a wide temperature range (-30 to 55 °C). This ensures reliable operation in diverse environments. Additionally, optimizing interfaces with fluoroethylene carbonate (FEC)-containing electrolytes enhances cycling stability, allowing LCO batteries to perform consistently over 350 cycles at a current density of 1.5 mA cm–2.

Tip: If your business requires custom battery solutions for compact devices, explore Large Power’s tailored offerings.

2.2 Safety Concerns and Thermal Stability

Safety remains a critical consideration for LCO batteries. While their high energy density is advantageous, it also introduces challenges related to thermal stability. You must account for the risks of thermal runaway, which can occur under extreme conditions like overcharging or internal shorts.

Key findings from safety tests highlight these concerns:

Conventional lithium-ion batteries may experience thermal runaway despite meeting safety standards.

Accelerating Rate Calorimetry (ARC) tests show that bare cells ignite at 173 °C after 1758 minutes, reaching peak temperatures of 418 °C.

SRL-coated cells delay thermal runaway by approximately 300 minutes, with a reduced maximum temperature of 354 °C, demonstrating improved safety.

Historical incidents further emphasize the importance of robust safety measures. Even batteries passing UL safety requirements have failed under normal use due to internal electrical shorts. To mitigate these risks, manufacturers implement advanced protective circuits and coatings to enhance thermal stability.

Pro Tip: Learn how Large Power integrates safety features into battery designs by visiting our Battery Management System guide.

2.3 Cost and Resource Challenges in Lithium Batteries

The reliance on cobalt in LCO batteries presents significant cost and resource challenges. Cobalt is a scarce and expensive material, with global reserves concentrated in regions like the Democratic Republic of Congo. Ethical concerns, including labor practices, further complicate its sourcing.

Market analyses reveal additional hurdles:

Recycling processes for lithium-ion batteries remain costly and inefficient, hindering widespread adoption.

Advanced recycling technologies require substantial investment, increasing operational costs.

The heterogeneity of lithium-ion batteries complicates standardization, leading to inefficiencies in recycling systems.

These factors drive the industry toward alternative chemistries like NMC and LiFePO4, which reduce cobalt dependency while maintaining competitive performance. However, LCO batteries continue to dominate applications where high energy density and compact design outweigh cost considerations.

🌱 Note: Discover how Large Power addresses sustainability challenges in battery production through our Sustainability Statement.

Part 3: Applications of LCO Batteries in 2025

3.1 Current Use Cases: Portable Electronics and Consumer Devices

The use of LCO batteries remains dominant in portable electronics and consumer devices due to their high energy density and compact design. Smartphones, laptops, and tablets rely on these batteries to deliver consistent power while maintaining lightweight and slim profiles. Their platform voltage of 3.7V ensures stable energy output, which simplifies battery pack configurations and enhances device performance.

Recent advancements in lithium batteries have improved the cycling stability of LCO cathodes. For example, configurations like 2% LAF-LCO achieve a capacity retention of 89.1% after 100 cycles, outperforming bare LCO, which retains only 44.5%. This improvement ensures longer-lasting performance for consumer electronics.

Configuration | Capacity Retention (%) | Capacity (mAh/g) after 100 cycles | Capacity (mAh/g) after 200 cycles | CE (%) after 5 cycles |

|---|---|---|---|---|

2% LAF-LCO | 89.1 | 185.3 | 170.7 | 99.64 |

Bare LCO | 44.5 | 92.6 | 68.2 | 98.86 |

The widespread adoption of LCO batteries in consumer electronics highlights their reliability and efficiency. Learn more about their applications in consumer electronics.

3.2 Emerging Applications: Medical Devices and IoT

In 2025, the use of LCO batteries expands into emerging fields like medical devices and IoT. Their compact design and high energy density make them ideal for powering portable medical equipment, such as wearable monitors and diagnostic tools. These devices require reliable energy sources to ensure uninterrupted operation in critical scenarios.

IoT applications also benefit from LCO batteries due to their ability to deliver consistent power in compact spaces. Smart sensors, connected devices, and industrial IoT systems leverage these batteries to maintain seamless communication and data processing. Their stable voltage platform simplifies integration into IoT networks, enhancing efficiency and reliability.

For medical applications, optimizing LCO cathodes with advanced electrolytes improves cycling stability, ensuring consistent performance across diverse environments. Explore more about medical battery solutions.

The versatility of LCO batteries positions them as a key component in the future of medical and IoT technologies. For tailored solutions, visit Large Power.

LCO batteries continue to dominate high-energy-density applications, offering compact designs and reliable performance. Their role in consumer electronics and medical devices remains unmatched. However, their limitations in energy storage systems and electric vehicles have shifted focus toward alternatives like NMC and LiFePO4.

Aspect | Details |

|---|---|

Current Role of LCO | High energy density, prevalent in consumer electronics. |

Market Trend | Decline in electric vehicle adoption due to geopolitical challenges related to cobalt. |

Shift in Chemistry | Movement towards alternatives with reduced cobalt content for enhanced sustainability. |

Future Implications (2025) | Increased demand for higher energy density and performance in battery technologies. |

Looking ahead, LCO batteries will remain vital in sectors prioritizing compact, high-energy solutions. Their evolution will likely focus on niche markets requiring advanced energy storage capabilities. For tailored solutions, explore Large Power’s custom battery offerings.

FAQ

1. What makes LCO Lithium batteries ideal for consumer electronics?

LCO Lithium batteries offer high energy density (180–230 Wh/kg) and a stable voltage platform (3.7V), ensuring compact designs and reliable performance for consumer electronics.

2. Can LCO Lithium batteries be used in medical devices?

Yes, their compact size and consistent energy output make them suitable for portable medical devices like wearable monitors and diagnostic tools.

3. How can Large Power assist with custom battery solutions?

Large Power provides tailored custom battery solutions for industries requiring high-energy-density batteries, ensuring optimal performance and design flexibility for your specific needs.