Contents

Lithium-sulfur (LSB) batteries deliver groundbreaking innovation in high-efficiency energy storage battery systems. You gain access to superior energy density and weight advantages, making these batteries ideal for industries requiring advanced solutions.

A lithium-sulfur (LSB) battery offers up to three times the energy storage capacity per unit weight compared to traditional lithium-ion batteries.

Its lightweight sulfur composition enhances performance, reducing overall battery weight.

With the highest theoretical energy density among battery chemistries, lithium-sulfur (LSB) technology transforms electric vehicles and renewable energy storage.

Key Takeaways

Lithium-sulfur batteries store three times more energy than lithium-ion ones. This makes them great for electric cars and green energy.

These batteries are lighter because they use sulfur. This improves how they work and lowers weight, which is important for planes and space travel.

Lithium-sulfur batteries cost less and are better for the planet. They use common materials and are easier to recycle than regular batteries.

Part 1: Understanding Lithium-Sulfur Batteries

1.1 What Is a Lithium Sulfur Battery?

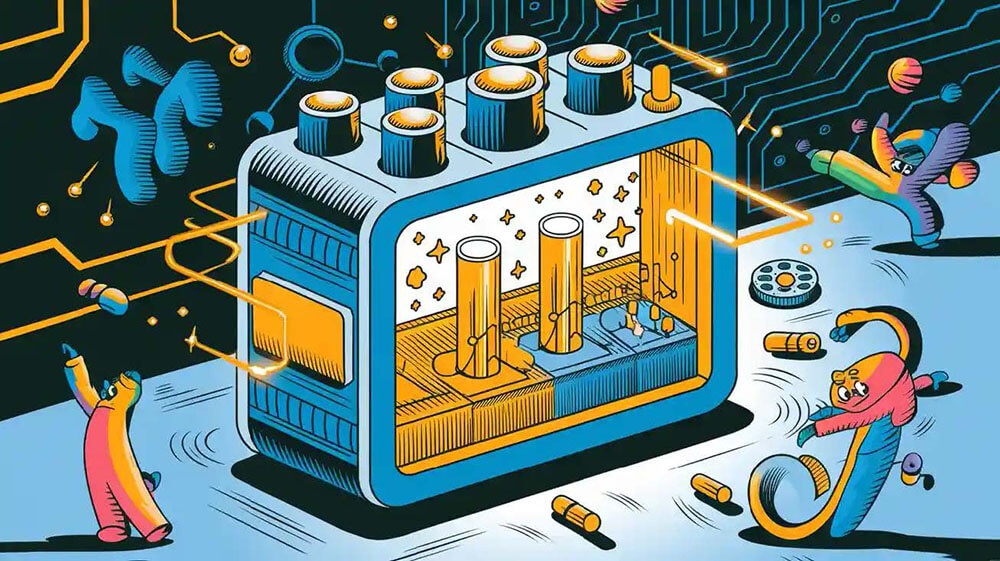

A lithium sulfur battery represents a significant leap in energy storage technology. Unlike traditional lithium-ion batteries, it uses sulfur as the cathode material and lithium as the anode. This unique composition allows it to achieve a theoretical energy density of up to 2,600 Wh/kg, far surpassing the capabilities of conventional battery chemistries. The lightweight nature of sulfur further enhances the battery’s performance, making it an ideal choice for applications requiring high energy efficiency and reduced weight.

The advantages of lithium sulfur battery technology extend beyond energy density. These batteries are more cost-effective due to the abundance and low cost of sulfur compared to materials like cobalt used in lithium-ion batteries. Additionally, their environmental impact is lower, as sulfur is easier to recycle and less resource-intensive. This makes lithium sulfur batteries a promising solution for industries prioritizing sustainability and cost-efficiency.

Feature | Lithium-Sulfur (Li-S) Batteries | Lithium-Ion (Li-ion) Batteries |

|---|---|---|

Charging Speed | Rapid charging capabilities | Standard charging times |

Cost | Lower due to inexpensive sulfur | Higher due to expensive materials like cobalt |

Environmental Impact | More eco-friendly, easier recycling | More resource-intensive materials |

Cycle Life | Shorter lifespan, ongoing research | Longer lifespan |

Safety | Safety challenges exist | Established safety record |

1.2 How Do Lithium-Sulfur Batteries Work?

The operation of a lithium sulfur battery relies on a unique electrochemical mechanism. During discharge, lithium ions move from the anode to the sulfur cathode, where they react to form lithium polysulfides. These polysulfides dissolve in the electrolyte and undergo further reactions, eventually forming lithium sulfide. This process releases a significant amount of energy, contributing to the high energy density of the battery.

During charge, the reverse reaction occurs. Lithium ions return to the anode, and sulfur is regenerated at the cathode. This cycle of dissolution and deposition is central to the performance of lithium sulfur battery systems. Studies have shown that the SeS2 positive electrodes play a critical role in optimizing these reactions. Advanced techniques like X-ray diffraction and transmission X-ray microscopy have revealed how the interaction of Li2S2 with different substrates influences reaction pathways and kinetics. These insights are crucial for enhancing the efficiency and reliability of lithium sulfur batteries.

The electrochemical mechanism of lithium sulfur batteries also highlights their potential for customization. By adjusting the Se-to-S ratio, you can optimize the nucleation and growth of sulfur particles, tailoring the battery’s performance to specific applications. This flexibility makes lithium sulfur batteries a versatile choice for industries ranging from electric vehicles to renewable energy storage.

Part 2: Structure and Challenges of Lithium-Sulfur Batteries

2.1 Key Components of Lithium-Sulfur Battery Packs

Lithium-sulfur battery packs consist of several critical components that define their performance and reliability. These include the sulfur cathodes, lithium anodes, electrolyte, and separators. Each plays a unique role in ensuring the battery’s functionality and addressing challenges like capacity fading and cycle stability.

Sulfur Cathodes: Sulfur serves as the cathode material, offering high theoretical energy density. However, its insulating nature requires the addition of conductive materials like carbon to enhance electron transfer.

Lithium Anodes: Lithium metal is used as the anode due to its high energy density. Its reactivity, however, poses challenges such as dendrite formation, which can compromise safety and performance.

Electrolyte: The electrolyte facilitates ion transport between the cathode and anode during charge and discharge cycles. Advanced formulations aim to reduce the polysulfide shuttle effect, a major problem with lithium sulfur battery systems.

Separators: Separators prevent direct contact between the cathode and anode while allowing ion flow. Innovations like corn protein-based separators have shown promise in enhancing cycle stability and reducing capacity fading.

Recent research has validated the design and reliability of these components:

Lithium-sulfur batteries achieve increased energy density, addressing range anxiety in electric vehicles.

Limited cycle life remains a challenge due to polysulfide dissolution and shuttle effects.

Ongoing studies focus on improving stability through new materials and formulations.

For example, a 2021 study demonstrated that sugar-based anode additives could prevent polysulfide release, enabling prototypes to achieve 1,000 charge cycles with a capacity of 700 mAh/g. These advancements highlight the potential for strong endurance and high stability in lithium-sulfur battery packs.

2.2 Structural Challenges in Lithium-Sulfur Batteries

Despite their advantages, lithium-sulfur batteries face structural challenges that hinder their widespread adoption. The most significant issues include the polysulfide shuttle effect, dendrite formation, and capacity fading.

Polysulfide Shuttle Effect: During discharge, lithium polysulfides dissolve in the electrolyte and migrate between the cathode and anode. This phenomenon leads to loss of active material and reduced cycle stability. Researchers have introduced interlayers and aramid nanofibers to mitigate this effect, facilitating lithium ion transfer and preventing dendrite formation.

Dendrite Formation: Lithium dendrites can form on the anode during repeated charge cycles, posing safety risks and reducing battery lifespan. A 2022 study revealed that using separators with corn protein significantly enhances performance, maintaining charge over 500 cycles.

Capacity Fading: The insulating nature of sulfur and the loss of active material during cycling contribute to capacity fading. Advanced sulfur–iodine crystalline materials discovered in 2024 offer self-healing properties, increasing electrical conductivity by 11 orders of magnitude and addressing this challenge effectively.

These structural challenges require innovative solutions to unlock the full potential of lithium-sulfur batteries. Engineering research continues to explore new materials and designs to improve cycle stability and reduce problems with lithium sulfur battery systems.

Part 3: Applications and Future of Lithium-Sulfur Batteries

3.1 Role of Lithium-Sulfur Batteries in Battery Systems

Lithium-sulfur batteries are reshaping modern energy systems with their high energy density and lightweight design. These batteries are particularly suited for industries requiring advanced battery packs, such as aerospace, electric vehicles, and renewable energy storage. Their ability to deliver up to three times the energy density of lithium-ion batteries makes them ideal for applications where weight and efficiency are critical.

The aerospace sector has embraced lithium-sulfur technology for satellites and unmanned aerial vehicles. With projections of 58,000 satellites to be launched by 2030, the demand for lightweight and high-capacity batteries continues to grow. Electric vehicles also benefit significantly from lithium-sulfur batteries. A 2025 study demonstrated a new design that retains 80% of its charge after 25,000 cycles, addressing range anxiety and lifecycle concerns. This innovation positions lithium-sulfur batteries as a key solution for the electric vehicle market, which saw a 35% increase in sales in 2023.

Government initiatives to phase out fuel-based vehicles by 2050 further amplify the importance of lithium-sulfur batteries. The International Energy Agency predicts that electric vehicles will account for 30% of the global market by 2030, driving demand for advanced battery systems.

3.2 Advancements in Solid-State Lithium-Sulfur Batteries

Solid-state lithium-sulfur batteries represent the next frontier in energy storage technology. These batteries eliminate flammable liquid electrolytes, enhancing safety and reducing risks of thermal runaway. Recent advancements in materials science have led to solid electrolytes with improved conductivity, enabling higher energy densities and better cycle stability.

Traditional lithium-ion batteries offer energy densities between 150–250 Wh/kg, while lithium-sulfur batteries can exceed 500 Wh/kg and theoretically approach 1,000 Wh/kg. Solid-state designs further optimize these capabilities by stabilizing the sulfur cathode and mitigating the polysulfide dissolution issue. Nanoengineering techniques have proven effective in enhancing cathode stability, while high-concentration electrolytes and protective coatings improve overall performance.

Comparative analyses highlight the integration of lithium bis(trifluormethylsulfonyl)amid (LiFTSi) in lithium-sulfur batteries for better compatibility with lithium metal. This innovation aligns with the growing demand for sustainable and efficient battery systems. As industries increasingly adopt solid-state lithium-sulfur batteries, their role in electric vehicles, aerospace, and renewable energy storage will expand significantly.

Lithium-sulfur batteries redefine energy storage with their unmatched energy density and lightweight design. You can leverage their potential to enhance electric vehicles, renewable energy systems, and other high-demand applications. Ongoing innovations, such as solid-state lithium-sulfur batteries, address challenges like the polysulfide shuttle effect, paving the way for commercial adoption.

FAQ

1. What industries benefit most from lithium-sulfur batteries?

Industries like aerospace, electric vehicles, and renewable energy storage benefit significantly. Their lightweight design and high energy density meet demanding performance requirements.

2. How do lithium-sulfur batteries support sustainability goals?

Lithium-sulfur batteries use abundant sulfur, reducing reliance on scarce materials like cobalt. Their recyclability aligns with sustainability initiatives.

Tip: For professional guidance on battery sustainability, visit Large Power.