Contents

To maintain optimal performance, it’s essential to follow battery load test a comprehensive guide to regularly evaluate your battery against the load it’s expected to handle. A battery load test a comprehensive guide helps identify how well the battery can sustain voltage under real-world conditions. This process is particularly critical for lithium battery packs, ensuring reliability and extending their lifespan. By conducting the test effectively, you can detect potential issues early, prevent unexpected failures, and optimize energy usage.

Key Takeaways

Testing batteries often is important to keep them working well and safe. It finds problems early and stops sudden failures.

Follow these steps for good testing: check the battery, attach the tester, test with a load, and study the results. This gives correct checks.

Take care of batteries and charge them the right way. Regular testing makes them safer and work better for longer.

Part 1: Battery Load Test – A Comprehensive Guide

1.1 What is a Battery Load Test?

A battery load test evaluates how well a battery performs under a simulated load, replicating real-world conditions. This process measures critical parameters such as voltage, capacity, and resistance to determine the battery’s ability to deliver power effectively. For lithium-ion batteries, this test is essential to ensure reliability and safety in demanding applications.

Load testing involves specialized equipment and software designed to simulate operational conditions. For instance, tools like the BCT40 tester can handle discharging currents up to 40A and test voltages ranging from 9V to 99V. These capabilities make it suitable for various lithium battery types, including LiFePO4 and NMC batteries. By conducting this test, you gain insights into the battery’s performance, enabling better decision-making for maintenance or replacement.

1.2 Why is it Important for Lithium Battery Packs?

Lithium battery packs power critical systems in industries such as robotics, medical devices, and infrastructure. Their performance directly impacts the efficiency and safety of these applications. A battery load test ensures that the battery can handle the required load without significant voltage drops or overheating.

Studies highlight the importance of load testing in understanding battery behavior. For example, electrochemical impedance spectroscopy (EIS) combined with machine learning can accurately predict lithium-ion battery performance. This underscores the role of load testing in identifying potential issues before they lead to failures.

1.3 Key Applications in Industrial and Commercial Use

Battery load tests are vital across various sectors. In industrial settings, they ensure uninterrupted power for machinery and equipment. In robotics, they verify the battery’s ability to support high-performance tasks. Medical devices rely on these tests to maintain operational safety and reliability. Similarly, infrastructure systems like transportation and security systems depend on load testing to prevent downtime.

The benefits of load testing extend beyond reliability. According to industry studies, it enhances accuracy, efficiency, and safety while providing valuable data for analysis. Here’s a summary:

Benefit | Description |

|---|---|

Accuracy and consistency | Ensures reliable performance evaluation and comparison between different batteries. |

Efficiency | Automates testing, saving time and resources while enabling high-throughput testing. |

Safety | Equipped with safety functions to prevent overcharging and over-discharging, ensuring operator safety. |

Data Analysis | Collects and analyzes performance data for in-depth assessment of capacity and efficiency. |

By incorporating battery load tests into your maintenance routine, you can optimize performance and extend the lifespan of lithium battery packs.

Part 2: How to Perform a Battery Load Test

2.1 Step 1: Inspect the Battery and Check State of Charge

Before you begin, inspect the battery for visible signs of damage, such as corrosion, swelling, or leakage. These issues can compromise safety and affect test results. Pay close attention to the terminals and connectors, ensuring they are clean and free of debris. A damaged battery should not undergo testing until repaired or replaced.

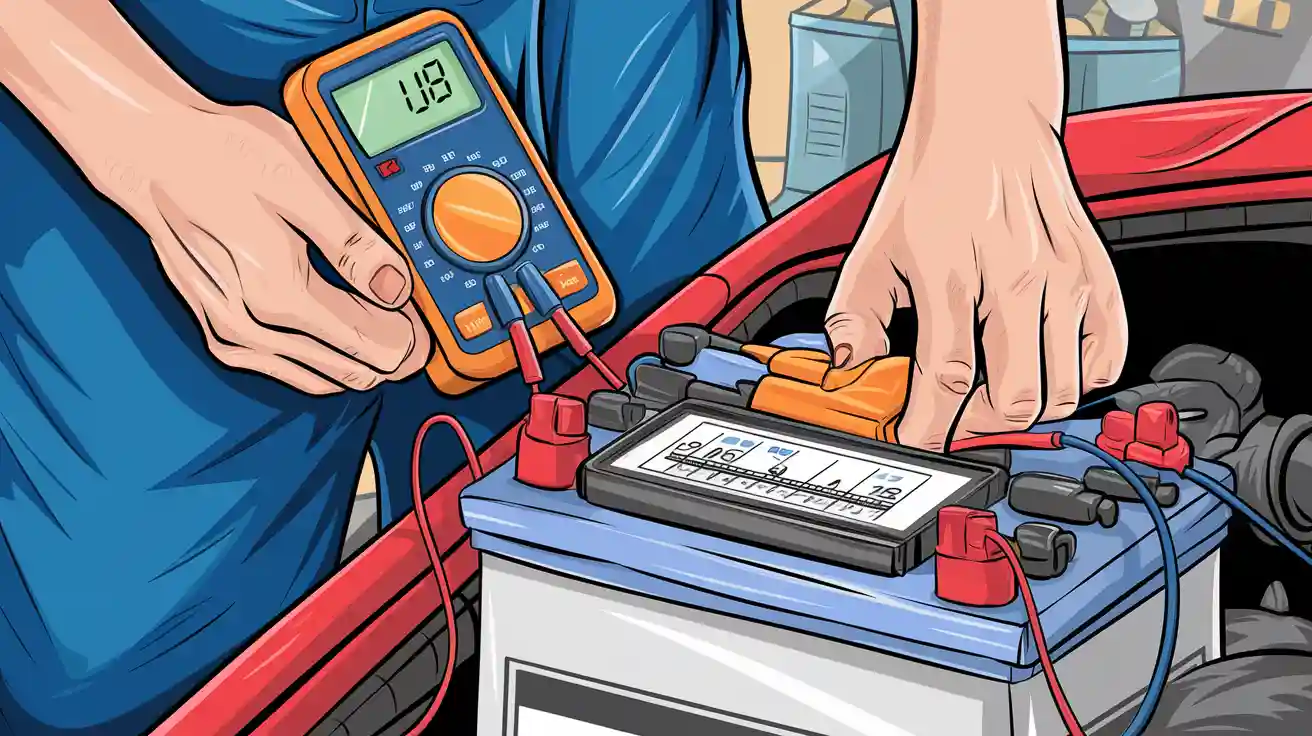

Next, check the state of charge using a multimeter. This step ensures the battery is adequately charged for testing. Lithium-ion batteries typically require a charge level of 80% or higher for accurate load testing. If the charge is insufficient, recharge the battery following manufacturer guidelines.

Tip: Always wear protective gear, such as gloves and safety goggles, when handling batteries to prevent accidents.

2.2 Step 2: Connect the Load Tester to the Battery

Proper connection of the load tester is crucial for accurate results. Begin by selecting a load tester compatible with your battery type. For lithium-ion batteries, ensure the tester supports the voltage range and current capacity of the battery pack.

Follow these steps to connect the load tester:

Attach the positive lead of the tester to the positive terminal of the battery.

Connect the negative lead to the negative terminal.

Verify the connections are secure to prevent interruptions during testing.

When connecting the tester, adhere to industry safety standards to avoid hazards. The table below outlines key safety requirements:

Test Type | Safety Requirements |

|---|---|

External Short Circuit Test | The battery must not ignite or rupture when subjected to external short circuits. |

Forced Internal Short Circuit Test | The battery must not ignite or rupture due to internal short circuits. |

Overcharge Test | The battery must not ignite or rupture during extended charging beyond capacity. |

Forced Discharge Test | The battery must not ignite or rupture during reverse polarity charging. |

Cycle Life Test | The battery must maintain a minimum specified capacity after repeated cycles. |

Crush Test | The battery must not ignite or rupture under physical deformation. |

Note: Ensure the load tester is calibrated and functioning correctly before proceeding.

2.3 Step 3: Apply the Load and Monitor Voltage

Once the load tester is connected, apply the load specified for your battery type. For lithium-ion batteries, this typically involves simulating the operational conditions the battery will face. Monitor the voltage drop as the load is applied.

Using a multimeter during this step can provide additional insights into the battery’s performance. Observe how the voltage behaves under load. A healthy battery will maintain a stable voltage, while a degraded battery may show significant drops.

Alert: If the battery overheats or emits unusual sounds during testing, stop immediately and investigate the issue.

2.4 Step 4: Record Results and Analyze Performance

After completing the test, record the results, including voltage readings, capacity measurements, and any anomalies observed. Compare these results against the manufacturer’s specifications to evaluate the battery’s performance.

Focus on identifying patterns that indicate degradation, such as reduced capacity or excessive voltage drops. If the battery fails to meet performance standards, consider maintenance or replacement.

Industry experts recommend the following best practices for effective analysis:

Gain a comprehensive understanding of the battery’s operational requirements.

Collect detailed data during testing for accurate evaluation.

Leverage existing datasets to identify trends and anomalies.

Use supervised learning techniques to predict future performance.

Collaborate with experienced engineers for advanced analysis.

Continuously monitor battery health to prevent failures.

Develop a clear plan for integrating findings into maintenance routines.

By following these steps, you can perform a battery load test effectively and ensure the reliability of your lithium battery packs.

Part 3: Interpreting the Results of a Battery Load Test

3.1 Understanding Voltage Drop and Capacity

Interpreting the voltage drop during a load test is critical for assessing the health of a battery. A stable voltage under load indicates a well-functioning battery, while a significant drop suggests potential issues such as reduced capacity or increased internal resistance. For lithium-ion batteries, the voltage should remain within the manufacturer’s specified range during testing. Deviations from this range may signal degradation or improper charging practices.

Capacity, another key parameter, reflects the battery’s ability to store and deliver energy. It is measured in ampere-hours (Ah) and compared against the nominal capacity provided by the manufacturer. A capacity below 80% of the nominal value often indicates that the battery has reached the end of its useful life.

Tip: Use a multimeter or advanced diagnostic tools to monitor voltage and capacity during testing. This ensures accurate data collection and helps you make informed decisions about battery performance.

3.2 Identifying Signs of Degradation in Lithium Battery Packs

Degradation in lithium battery packs can manifest in various ways, including reduced capacity, increased internal resistance, and thermal instability. Identifying these signs early can prevent failures and extend the battery’s lifespan. Below is a table summarizing key diagnostic criteria for detecting degradation:

Diagnostic Criteria | Description |

|---|---|

Open-Circuit Voltage (OCV) | Analysis of OCV to identify degradation modes |

State of Health (SOH) | Ratio of present capacity to nominal capacity |

Loss of Lithium Inventory (LLI) | Significant degradation mode affected by temperature |

Loss of Cathode Active Material (LAMCa) | Major degradation mode observed |

Increased Internal Resistance | Indicator of battery health decline |

Thermal Runaway | Critical sign of potential failure |

Gas Evolution | Indicates chemical changes in the battery |

For lithium-ion batteries, the State of Health (SOH) is a crucial metric. It compares the current capacity or resistance to that of a new battery. A SOH below 70% often signals the need for replacement. Additionally, monitoring the Remaining Useful Life (RUL) can help you plan maintenance schedules effectively.

Term | Definition |

|---|---|

State of Health (SOH) | Ratio of present capacity to nominal capacity or present resistance to fresh battery resistance |

Remaining Useful Life (RUL) | Remaining cycles before the end of service life (when SOH reaches 70% or 80%) |

Alert: If you notice signs like excessive heat, unusual sounds, or gas evolution during testing, discontinue use immediately. These could indicate severe degradation or safety risks.

3.3 Determining Maintenance or Replacement Needs

Once you interpret battery load test results, the next step is to decide whether maintenance or replacement is necessary. Batteries showing minor issues, such as slightly reduced capacity or increased resistance, may benefit from recalibration or reconditioning. However, batteries with significant degradation, such as a SOH below 70%, should be replaced to ensure reliability and safety.

To determine the best course of action, consider the following steps:

Compare test results with the manufacturer’s specifications.

Evaluate the battery’s performance in its intended application.

Assess the cost-effectiveness of maintenance versus replacement.

Consult with experts or use predictive analytics tools for advanced diagnostics.

Callout: For custom battery solutions tailored to your specific needs, consult with Large Power.

Regular maintenance, including cleaning terminals and monitoring charge cycles, can prolong the life of lithium battery packs. Implementing a robust Battery Management System (BMS) can also enhance performance and safety. Learn more about BMS operations and components here.

By understanding how to interpret battery load test results, you can make informed decisions that optimize performance, reduce downtime, and extend the lifespan of your lithium battery packs.

Regular battery load testing plays a vital role in ensuring the reliability and longevity of lithium battery packs. By following the outlined steps—inspecting the battery, connecting the tester, applying the load, and analyzing results—you can identify potential issues early. Adopting best practices, such as routine maintenance and proper charging, helps you maximize battery performance and avoid unexpected failures.

Tip: Consistent testing not only extends the life of your battery but also enhances safety and efficiency in its applications.

FAQ

1. What tools do you need for a diy battery load test?

You need a multimeter, a load tester, and safety gear. These tools ensure accurate results and protect you during the diy process.

2. How often should you perform a diy battery load test?

Perform the test every six months. Regular testing helps you identify issues early and maintain your battery’s performance.

3. Can you test any battery with a diy battery load test?

You can test most batteries, including lithium-ion types. Ensure the load tester matches the battery’s voltage and capacity specifications.