Contents

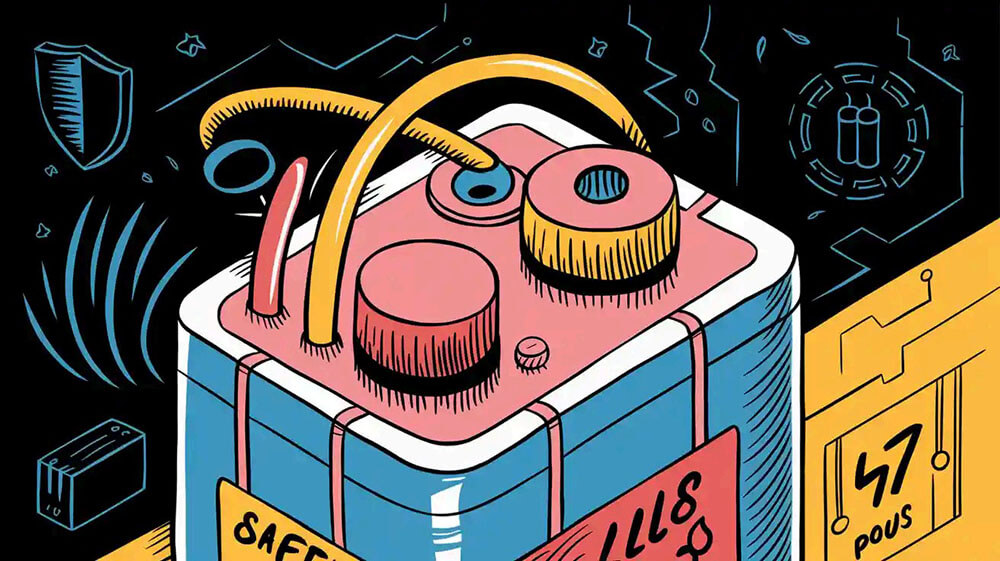

Safety vents are crucial components in ensuring the safety of lithium batteries, particularly under extreme conditions. The Safety Vent Lithium battery is designed to effectively release pressure, mitigating risks such as thermal runaway and potential explosions. The significance of safety vents is highlighted by NFPA 855, which mandates deflagration venting to manage rapidly expanding gases. This innovation is indispensable across industries like medical, robotics, and infrastructure, ensuring dependable performance and enhanced safety in lithium battery applications.

Key Takeaways

Safety vents are important for lithium batteries. They stop explosions by letting out pressure when it gets too high.

In risky uses like medical tools and robots, safety vents keep batteries working well and stop overheating or fires.

Adding safety vents with other tools like fuses makes batteries safer and follows safety rules.

Part 1: What Are Safety Vents?

1.1 Definition and Purpose of Safety Vents

Safety vents are integral to the design of lithium batteries, serving as a critical safety mechanism. They protect users from potential hazards by releasing internal pressure when it reaches a critical threshold. This prevents unpredictable explosions caused by gas build-up.

The primary purpose of safety vents is to ensure the safe operation of lithium batteries under extreme conditions. By managing pressure effectively, they enhance battery longevity, maintain performance, and comply with industry safety standards.

1.2 Key Features of Safety Vent Lithium Battery Design

The design of a safety vent lithium battery incorporates several essential features to ensure optimal performance and safety. These include:

Pressure-sensitive mechanisms: Safety vents activate only when internal pressure exceeds a predefined limit.

Thermal responsiveness: They respond to temperature changes, ensuring venting occurs before thermal runaway.

Durable materials: High-quality materials withstand operational stresses while maintaining venting reliability.

Regulatory compliance: Designs adhere to safety standards, ensuring safe deployment across industries.

These features make safety vent lithium batteries indispensable in applications like medical devices, robotics, and infrastructure, where safety and reliability are paramount.

1.3 Role in Battery Venting and Pressure Management

Safety vents play a pivotal role in venting and pressure management within lithium batteries. They release gases generated during chemical reactions, preventing pressure build-up that could lead to catastrophic failures. Experimental studies highlight their effectiveness:

Experimental Condition | Key Result | Implication for Safety Design |

|---|---|---|

Two venting caps with known geometries | Quantified key parameters of battery venting and validated CFD models. | Enables precise design optimization for gas flow efficiency and pressure thresholds. |

Ambient pressure (100 kPa, 70 kPa, 40 kPa) and temperature (−15 °C, 0 °C, 25 °C) | Lowered thermal runaway intensity, reducing maximum temperature from 811.9 °C to 667.5 °C. | Confirms venting efficacy in extreme environments, guiding thermal management strategies. |

Safety valve operation | Emitted sound at a specific frequency, reducing internal pressure and preventing explosions. | Acoustic signatures can be used for real-time failure detection and pressure monitoring. |

By managing pressure effectively, safety vents ensure optimal operating conditions, contributing to the efficiency and safety of energy storage systems.

Part 2: Why Are Safety Vents Necessary?

2.1 Risks in Lithium Batteries: Thermal Runaway and Overheating

Lithium-ion batteries, widely used across industries, face inherent risks such as thermal runaway and overheating. These risks arise from internal or external factors, including overcharging, physical damage, or battery management system failures. When a lithium-ion battery experiences thermal runaway, it undergoes an uncontrollable chain reaction, releasing heat and gases that can lead to catastrophic outcomes. Overheating exacerbates this process, further increasing the likelihood of failure.

Several studies highlight the severity of these risks:

Overcharging often triggers thermal runaway, especially in poorly managed battery systems.

Fire incidents caused by thermal runaway demonstrate how heat transfer within battery packs can escalate the situation.

Gas mixtures vented during thermal runaway contain flammable hydrocarbons, which can ignite if concentrations exceed 25% of the Lower Flammability Limit (LFL), as outlined by NFPA 855.

These risks emphasize the need for robust safety mechanisms, such as battery venting systems, to manage pressure and prevent hazardous conditions.

2.2 How Safety Vents Prevent Catastrophic Failures

Safety vents play a critical role in mitigating the risks associated with lithium-ion batteries. By releasing internal pressure and venting gases, they prevent the buildup of flammable mixtures that could lead to explosions. This mechanism ensures that batteries operate within safe parameters, even under extreme conditions.

Case studies underscore the importance of safety vents:

The 2019 Arizona Public Service BESS explosion occurred when accumulated gases ignited after a HAZMAT team introduced fresh air. Proper venting could have prevented this escalation.

Safety vents help maintain gas concentrations below critical thresholds, reducing the risk of ignition and ensuring compliance with safety standards like NFPA 855.

By integrating safety vents into battery designs, manufacturers can significantly reduce the likelihood of catastrophic failures, safeguarding both equipment and personnel.

2.3 Importance in High-Risk Applications (e.g., Medical, Robotics, Security Systems)

Safety vents are indispensable in high-risk applications where lithium-ion batteries power critical systems. Industries such as medical, robotics, and security systems demand reliable and safe energy storage solutions to ensure uninterrupted operations. For example:

Medical devices: Equipment like portable ventilators and defibrillators rely on lithium-ion batteries for consistent performance. Safety vents protect these devices from overheating, ensuring patient safety.

Robotics: Industrial robots and autonomous systems require robust batteries to operate in demanding environments. Safety vents prevent thermal runaway, enhancing operational reliability.

Security systems: Surveillance cameras and alarm systems depend on uninterrupted power. Safety vents mitigate risks, ensuring these systems function during emergencies.

In these applications, the failure of a single battery can have far-reaching consequences. Safety vents provide an additional layer of protection, ensuring that lithium-ion batteries meet the stringent safety requirements of these industries.

For custom battery solutions tailored to your specific needs, explore Large Power’s Custom Battery Solutions.

Part 3: How Do Safety Vents Work?

3.1 Mechanism of Battery Venting and Gas Release

Safety vents in lithium-ion batteries serve as a critical fail-safe mechanism, ensuring the controlled release of gases during hazardous conditions. When internal pressure builds up due to chemical reactions or external factors, the vent opens to release the accumulated gases. This process prevents the battery casing from rupturing, which could lead to catastrophic failures.

The venting mechanism operates through a pressure-sensitive design. As the internal pressure reaches a critical threshold, the vent ruptures at a pre-determined weak point. This allows gases, such as oxygen and flammable hydrocarbons, to escape safely. By managing gas release, safety vents mitigate thermal runaway behaviors and reduce the risk of explosions.

In high-risk applications like medical devices, robotics, and security systems, venting plays a pivotal role in maintaining operational safety. For instance, in medical equipment such as portable ventilators, venting ensures that the battery remains stable even under prolonged use. Similarly, in robotics, venting safeguards the battery pack from overheating during intensive operations. These examples highlight the importance of venting in ensuring reliability across diverse industries.

3.2 Activation Conditions: Pressure and Temperature Thresholds

Safety vents activate under specific pressure and temperature conditions, designed to align with the battery’s operational limits. The activation thresholds depend on factors such as the battery chemistry, vent design, and environmental conditions. For example, in LiFePO4 batteries, the temperature threshold for vent activation is approximately 137 °C. This threshold is critical for preventing thermal runaway features, as it allows the vent to release gases before the situation escalates.

Several parameters influence the venting process:

Vent area: A larger vent area facilitates quicker gas release, reducing internal pressure more effectively.

Gas amount: The volume of gas generated during chemical reactions determines the pressure buildup.

Burst pressure: The vent’s design ensures it ruptures only when the internal pressure exceeds a safe limit.

By adhering to these thresholds, safety vents provide a reliable mechanism to manage thermal runaway processes. This ensures that lithium-ion batteries operate safely, even under extreme conditions.

Safety vents are indispensable in ensuring lithium battery safety. They mitigate thermal runaway risk by managing gas release and pressure buildup. Their role becomes critical in industries like medical, robotics, and infrastructure, where safety measures must meet stringent safety regulations. For instance, LiFePO4 batteries, despite their weakly oxidizing cathodes, pose significant thermal runaway characteristics due to low-LEL gas generation. NMC batteries, with highly oxidizing cathodes, release more CO and CO2, increasing thermal runaway risk. Properly designed safety devices, integrated with other safety measures, enhance battery pack safety and ensure compliance with safety regulations.

FAQ

1. What is the purpose of safety valves in lithium-ion batteries?

Safety valves release internal pressure when it exceeds safe limits. This prevents battery casing rupture, reducing the risk of thermal runaway and ensuring operational safety.

As lithium batteries power diverse applications, safety vents will remain vital in advancing safety standards. For custom battery solutions tailored to your needs, visit Large Power’s Custom Battery Solutions.

2. How do safety valves enhance battery safety in high-risk applications?

Safety valves protect lithium-ion batteries in critical systems by venting gases during hazardous conditions.

3. Can safety valves prevent all battery failures?

Safety valves mitigate risks like overpressure and overheating. However, they work best when integrated with other safety features, such as fuse links and cell protection devices.