Contents

As industries like medical, robotics, and security systems increasingly rely on lithium-ion batteries, ensuring their safe usage becomes critical. Poor risk management can lead to catastrophic failures, including fires, toxic leaks, and operational shutdowns. Proactively adopting robust risk management lithium battery strategies in 2025 will safeguard your business from these hazards.

Key Takeaways

Lithium-ion batteries can be dangerous, like causing fires from overheating. Knowing these dangers is very important for safety.

Storing and handling batteries the right way lowers risks a lot. Keep them at the right temperature and humidity.

Checking and fixing battery packs often finds problems early. This stops overheating and keeps them working well.

Part 1: Understanding Lithium Battery Risks

1.1 Fire and Thermal Runaway Hazards in Lithium-Ion Batteries

Lithium-ion batteries, widely used across industries such as infrastructure and consumer electronics, pose significant fire hazards if not managed properly. One of the most critical risks is thermal runaway, a chain reaction triggered by overheating. This phenomenon can escalate rapidly, leading to battery fires or even explosions.

A recent statistical report highlights a 28% increase in thermal runaway incidents between 2019 and 2023, with an average of two incidents per week. The majority of these incidents occurred in devices like smartphones (82%), laptops (41%), and wireless headphones (39%). Alarmingly, 87% of these events took place on aircraft, often near passenger seats. However, proactive measures prevented 85% of these incidents from escalating into full-blown fires.

Key Takeaways | Details |

|---|---|

Incidents Increase | 28% rise in thermal runaway incidents from 2019-2023. |

Common Devices | 82% smartphones, 41% laptops, 39% wireless headphones, 36% tablets. |

Incident Location | 87% of incidents occur on aircraft, primarily near passenger seats. |

Prevention Success | 85% of incidents addressed before reaching fire/explosion stage. |

To mitigate these risks, you must implement robust fire safety protocols. These include using advanced fire containment systems and conducting regular risk assessments. By doing so, you can significantly reduce the likelihood of thermal runaway and its associated dangers.

1.2 Risks of Improper Storage and Handling in Industrial Settings

Improper storage and handling of lithium-ion batteries in industrial environments can lead to severe safety issues. These batteries are highly sensitive to temperature extremes. Exposure to excessive heat or cold can compromise their structural integrity, increasing the risk of overheating and fire hazards. Physical damage, such as dropping or piercing, can also result in short circuits, which may trigger thermal runaway.

For example, in industrial applications like robotics and automated systems, improper storage can disrupt operations and pose safety risks to personnel. Ensuring proper storage conditions, such as maintaining optimal temperature and humidity levels, is essential. Additionally, you should train employees on safe handling practices to minimize the risk of accidents.

1.3 Environmental Factors and Their Impact on Battery Safety

Environmental factors play a crucial role in the safety and performance of lithium-ion batteries. Extreme temperatures, high humidity, and exposure to water or corrosive substances can degrade battery components. This degradation not only reduces the battery’s lifespan but also increases the likelihood of overheating and fire risks.

In sectors like medical and security systems, where uninterrupted power supply is critical, environmental factors can have catastrophic consequences. For instance, high temperatures in outdoor infrastructure applications can accelerate battery aging, leading to potential failures. To address these challenges, you should invest in weather-resistant battery enclosures and conduct regular maintenance checks.

Tip: Incorporating advanced battery management systems (BMS) can help monitor environmental conditions and prevent potential risks. These systems provide real-time data, enabling you to take corrective actions before issues arise.

By understanding these risks and implementing effective strategies, you can enhance the safety and reliability of lithium-ion batteries in your operations.

Part 2: Strategies for Effective Risk Management Lithium Battery

2.1 Best Practices for Safe Storage of Lithium-Ion Batteries

Proper storage of lithium-ion batteries is essential to minimize safety risks such as overheating, short circuiting, and thermal runaway. You should store batteries in a cool, dry environment with controlled temperature and humidity levels. Avoid exposing them to direct sunlight or extreme temperatures, as these conditions can compromise their structural integrity and increase the likelihood of fire hazards.

To further enhance safety, consider the following best practices:

Use fire containment systems: These systems can isolate and suppress potential fires, reducing the risk of escalation.

Organize storage areas: Keep batteries separated to prevent short circuiting caused by accidental contact.

Inspect storage conditions regularly: Conduct routine checks to ensure compliance with safety standards.

A study comparing the failure rates of high-quality and lesser-quality lithium-ion cells highlights the importance of quality in storage safety:

Quality of Cells | Estimated Failure Rate |

|---|---|

High-quality cells | 1 in 10 million |

Lesser quality cells | Poorer field performance |

By implementing these measures, you can significantly reduce the risks associated with improper storage and ensure the longevity of your battery inventory.

2.2 Safe Charging Practices to Prevent Battery Fires

Charging lithium-ion batteries safely is critical to preventing battery fires and ensuring operational reliability. Overcharging or using incompatible chargers can lead to overheating and thermal runaway. To mitigate these risks, you should adopt the following practices:

Use certified chargers: Always use chargers designed specifically for your battery type to avoid overcharging.

Monitor charging environments: Ensure that charging stations are well-ventilated and free from flammable materials.

Avoid prolonged charging: Disconnect batteries once fully charged to prevent overheating.

Empirical data demonstrates the effectiveness of safe charging practices in reducing fire incidents:

In the United States, gasoline-powered internal combustion engine (ICE) cars experienced approximately 1,530 fires per 100,000 sold.

In contrast, pure electric vehicles (EVs) had only 25 fires per 100,000 sold.

In Sweden, the fire rate for EVs was 0.004%, compared to 0.08% for gasoline or diesel vehicles.

These statistics underscore the importance of adhering to safe charging protocols to minimize safety risks and enhance battery performance.

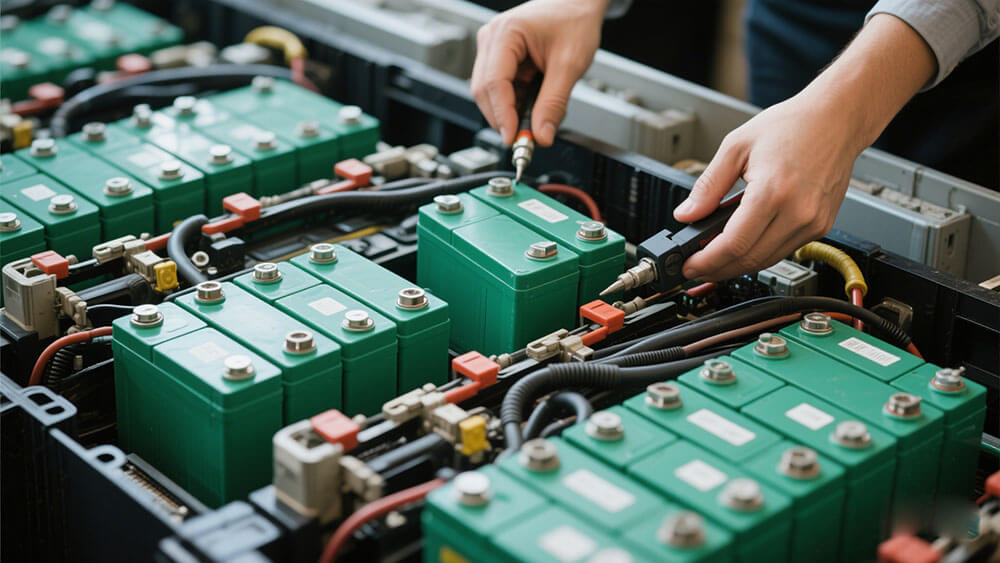

2.3 Regular Maintenance and Inspection Protocols for Battery Packs

Regular inspections and maintenance are vital for ensuring the safety and efficiency of lithium-ion batteries. By identifying potential issues early, you can prevent short circuiting, overheating, and other safety risks. Establishing a comprehensive maintenance schedule is crucial for industries like medical and robotics, where uninterrupted power supply is critical.

Key maintenance practices include:

Inspecting battery packs for physical damage: Look for signs of swelling, corrosion, or leakage.

Testing charge levels: Ensure batteries operate within optimal voltage ranges to maximize their lifespan.

Replacing aging batteries: Remove batteries that no longer meet performance standards to avoid operational disruptions.

Reducing the charge level to 50% state of charge (SOC) can increase the battery’s lifespan by 44–130%. By following these guidelines, you can optimize battery performance and reduce the risk of failures.

2.4 Emergency Response Planning for Lithium Battery Incidents

Despite preventive measures, emergencies involving lithium-ion batteries can still occur. Having a robust emergency response plan is essential to mitigate damage and ensure the safety of personnel. Your plan should include the following components:

Fire safety training: Train employees to handle battery fires using appropriate extinguishing agents, such as Class D fire extinguishers.

Evacuation protocols: Establish clear procedures for evacuating affected areas during an incident.

Emergency equipment: Equip storage and charging areas with fire containment systems and protective gear.

Battery management systems (BMS) can play a crucial role in emergency preparedness. These systems monitor battery conditions in real time, providing alerts for potential issues like overheating or short circuiting. By integrating BMS into your operations, you can detect and address risks before they escalate.

Tip: Regularly review and update your emergency response plan to align with the latest safety standards and industry best practices.

By prioritizing emergency preparedness from Large Power, you can protect your assets, employees, and operations from the consequences of lithium battery incidents.

Part 3: Leveraging Technology to Mitigate Lithium-Ion Battery Risks

3.1 Battery Management Systems (BMS) for Risk Monitoring

Battery Management Systems (BMS) play a pivotal role in ensuring the safety and reliability of lithium-ion batteries. These systems monitor critical parameters such as temperature, voltage, and current in real time. By doing so, they help prevent battery fires caused by overheating or overcharging. For industries like robotics and medical, where uninterrupted power is essential, BMS provides an added layer of protection.

You can use BMS to detect anomalies early and take corrective actions before they escalate into emergencies. Advanced BMS solutions also offer predictive maintenance features, enabling you to replace aging batteries proactively. This reduces downtime and enhances operational efficiency.

Tip: Choose a BMS that supports remote monitoring to manage battery systems across multiple locations effectively.

3.2 Fire Suppression Systems for Lithium Battery Storage

Fire suppression systems are essential for mitigating risks associated with lithium battery storage. These systems are designed to contain and extinguish fires quickly, minimizing damage and ensuring safety. For example, in industrial settings, fire suppression systems can prevent small incidents from escalating into large-scale disasters. Implementing these systems ensures compliance with safety standards and reduces the risk of battery fires in storage facilities.

3.3 Predictive Analytics and AI for Risk Prevention in Industrial Applications

Predictive analytics and AI are transforming how you manage lithium battery risks in industrial applications. These technologies analyze vast amounts of data to identify patterns and predict potential failures. For example, AI algorithms can detect early signs of overheating or short circuits, allowing you to address issues before they lead to safety incidents.

These technologies are particularly valuable in sectors like infrastructure and consumer electronics, where operational reliability is critical. By leveraging predictive analytics and AI, you can enhance safety, reduce downtime, and optimize battery performance.

Note: Integrating AI-driven solutions into your operations not only improves safety but also aligns with sustainability goals. Learn more about sustainability initiatives here.

Understanding lithium battery risks and implementing effective strategies are essential for ensuring safety and operational efficiency. Advanced technologies, such as battery management systems and fire suppression systems, provide critical safeguards against potential hazards.

Lithium resource supply risks have escalated, with predictions indicating continued high-risk levels for key materials like manganese and cobalt.

Effective management practices, including proper storage, regular maintenance, and employee training, mitigate these risks.

Adopting these measures, along with a robust emergency response plan, ensures the safe disposal of damaged batteries and enhances overall safety. Explore tailored solutions to meet your specific needs through Custom Battery Solutions from Large Power.

FAQ

1. What industries benefit most from lithium battery solutions?

Lithium batteries are essential in industries like medical, robotics, and infrastructure, offering reliable power for critical applications.

2. How can you ensure the safety of lithium batteries in industrial environments?

Implement proper storage, regular maintenance, and advanced monitoring systems like BMS. These measures reduce risks and enhance battery performance in demanding industrial settings.

3. Why choose Large Power for custom battery solutions?

Large Power provides tailored solutions designed to meet your specific operational needs.