Contents

Understanding different battery sizes is essential for optimizing industrial and commercial operations. Lithium-ion technology drives innovation in energy storage, with the market projected to grow from USD 75.2 billion in 2024 at a CAGR of 15.8% through 2034. Cylindrical battery dimensions directly influence energy density, performance, and pack compatibility, making size selection critical for achieving operational efficiency and sustainability.

Key Takeaways

Pick the right battery size for what you need. The 18650 is cheaper and works for medium energy use. The 21700 and 26650 hold more power for bigger jobs.

Think about energy storage, fit, and price when choosing a battery. Balance these helps your system work well and save energy.

Ask Large Power for help with tricky battery choices. They can guide you to design the best battery pack for your needs.

Part 1: Common Cylindrical Lithium-Ion Battery Sizes

1.1 18650: Dimensions, Capacity, and Applications

The 18650 cylindrical lithium-ion battery is one of the most widely used battery sizes in the market. With a diameter of 18mm and a height of 65mm, it offers a compact physical size that balances energy density and performance. Depending on the chemistry system, the nominal voltage is either 3.2 volts, or it falls between 3.6 and 3.7 volts, while its capacity ratings vary from 1500mAh to 3500mAh. This makes it ideal for applications requiring moderate energy storage, such as healthcare equipments, robotics, and consumer electronics. The battery’s capacity and voltage ensure reliable performance across various devices, but factors like temperature and manufacturing quality can influence its longevity.

1.2 21700: Higher Capacity and Industrial Use Cases

The 21700 battery, with a diameter of 21mm and a height of 70mm, represents a step forward in cylindrical lithium-ion battery technology. It provides a larger capacity, ranging from 3000mAh to 5000mAh, making it suitable for high-demand applications like electric vehicles and solar lighting systems. Its increased physical size allows for higher energy density, which translates to longer operational times and improved efficiency. This battery size has gained popularity in industrial sectors due to its ability to deliver consistent power output and support advanced energy storage systems.

1.3 26650: Larger Size for High-Power Applications

The 26650 battery, measuring 26mm in diameter and 65mm in height, is designed for high-power applications. It offers a higher capacity than the 18650, making it suitable for electric vehicles, power banks, and commercial pulse power tools. Studies have shown that this battery performs well under high-rate discharge conditions, although thermal management is crucial to maintain its efficiency. Its robust design and larger capacity make it a preferred choice for industries requiring reliable and long-lasting energy solutions.

1.4 Custom and Less Common Battery Sizes

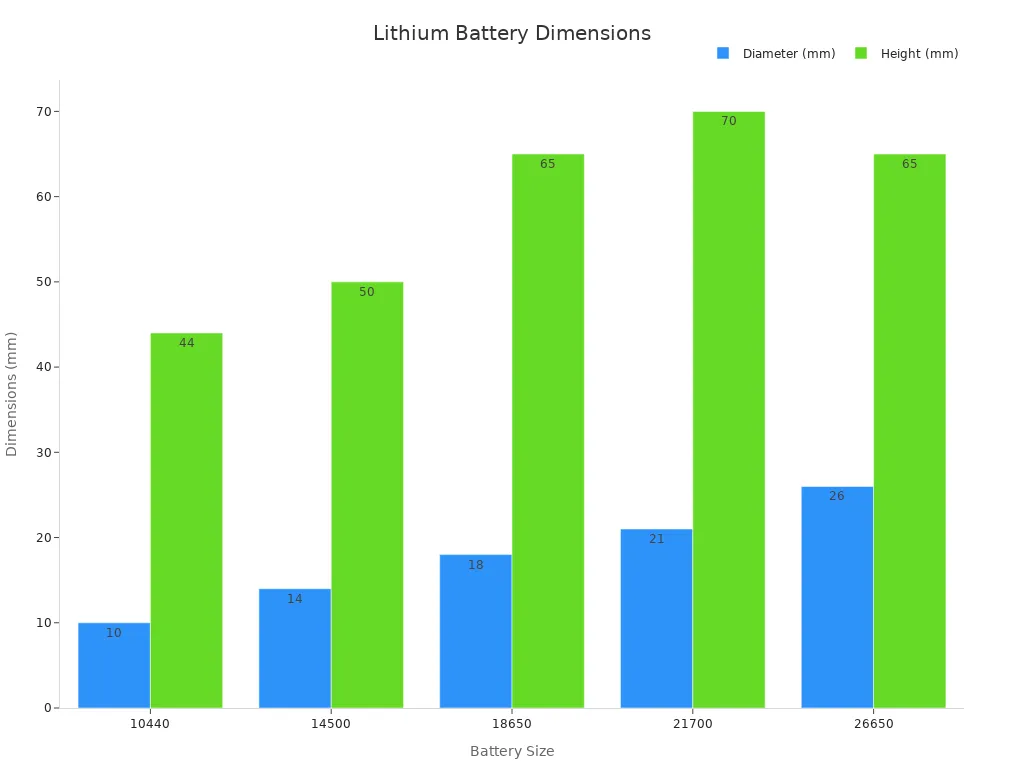

While 18650, 21700, and 26650 are the most common sizes, other cylindrical lithium-ion battery sizes like 10440 and 14500 cater to niche applications. For instance, the 10440 battery, with a diameter of 10mm and a height of 44mm, is used in micro flashlights and mini stereos. The 14500 battery, slightly larger at 14mm by 50mm, powers LED flashlights and wireless speakers. These custom sizes offer flexibility for specialized devices, ensuring compatibility and optimal performance.

Battery Size | Diameter (mm) | Height (mm) | Capacity (mAh) | Common Applications |

|---|---|---|---|---|

10440 | 10 | 44 | Few hundred | Micro flashlights, mini stereos |

14500 | 14 | 50 | < 1000 | LED flashlights, wireless speakers |

18650 | 18 | 65 | 1500-3500 | Healthcare equipment, robotics, and consumer electronics |

21700 | 21 | 70 | 3000-5000 | Unmanned survey vessels |

26650 | 26 | 65 | Higher than 21700 | Unmanned ground vehicle (UGV) |

Part 2: Key Factors for Choosing the Right Battery Size

2.1 Application-Specific Requirements for Battery Packs

Selecting the right cylindrical lithium-ion battery depends on the specific requirements of your application. Industrial battery packs often demand high energy density and consistent performance to support critical operations. For instance, NCM batteries, with an energy density range of 160–270 Wh/kg and a cycle life of 1,000–2,000, are ideal for applications requiring compact designs and moderate longevity. In contrast, LiFePO4 batteries, offering 2,000–5,000 cycles and a density of 100–180 Wh/kg, suit systems prioritizing durability over compactness. Understanding these parameters ensures your battery pack delivers optimal capacity and reliability.

2.2 Compatibility with Industrial Systems and Devices

Compatibility plays a pivotal role in battery selection. Cylindrical lithium-ion batteries must align with the voltage and capacity requirements of your energy storage systems. For example, integrating a battery management system ensures safe operation by monitoring voltage levels and preventing thermal runaway. Additionally, industrial devices often require batteries with specific dimensions to fit seamlessly into existing designs. Choosing the wrong size or chemistry can compromise performance and increase maintenance costs.

2.3 Trade-offs Between Energy Density, Size, and Cost

Balancing energy density, size, and cost is crucial for industrial applications. High energy density batteries, such as LCO (180–230 Wh/kg), offer compact solutions but come with higher costs and shorter lifespans (500–1,000 cycles). On the other hand, LiFePO4 batteries provide cost-effective options with longer lifespans but lower energy density. The table below highlights these trade-offs:

Battery Chemistry | Energy Density | Cost | Lifespan | Applications |

|---|---|---|---|---|

NCM | 160–270 Wh/kg | Moderate to High | 1,000–2,000 | portable electronics |

LCO | 180–230 Wh/kg | High | 500–1,000 | |

LiFePO4 | 100–180 Wh/kg | Low to Moderate | 2,000–5,000 | Grid storage, industrial equipment |

2.4 Availability and Supply Chain Considerations

Supply chain dynamics significantly impact battery availability. Market research indicates that sourcing raw materials for lithium-ion batteries, such as cobalt and nickel, presents challenges due to geopolitical and environmental factors. The global energy storage market must grow 14-fold to meet the 1,200 GW target by 2030, emphasizing the need for reliable supply chains. Collaborating with trusted suppliers and leveraging robust research methodologies ensures consistent access to high-quality batteries for your industrial needs.

Part 3: Comparing the Advantages and Disadvantages of Popular Battery Sizes

3.1 18650: Pros, Cons, and Use Cases

The 18650 cylindrical lithium-ion battery remains a cornerstone in energy storage solutions. Its compact size and moderate capacity make it a versatile choice for various applications.

Advantages:

High availability due to widespread adoption.

Balanced energy density and performance, suitable for portable devices.

Cost-effective for applications requiring multiple cells in a pack.

Disadvantages:

Limited capacity compared to newer sizes like 21700.

Requires more cells to achieve higher energy storage, increasing pack complexity.

Use Cases:

You’ll find 18650 batteries in healthcare equipment, robotics, and consumer electronics. Their reliability and affordability make them ideal for devices requiring moderate energy density and consistent performance.

3.2 21700: Pros, Cons, and Use Cases

The 21700 battery offers a significant upgrade in capacity and performance over the 18650. Its larger size supports advanced energy storage systems.

Advantages:

Larger capacity, reducing the number of cells needed in a pack.

Higher discharge rates, ideal for high-drain devices like electric vehicles.

Cost efficiency, with a system cost of $155/kWh compared to $171/kWh for 18650 cells.

Disadvantages:

Increased size and weight may limit compatibility with smaller devices.

Higher upfront costs compared to older cylindrical lithium-ion battery models.

Use Cases:

This battery powers unmanned survey vessels and premium performance battery packs. Its ability to deliver consistent power output makes it a preferred choice for industrial applications.

3.3 26650: Pros, Cons, and Use Cases

The 26650 battery is designed for high-power applications, offering robust performance and durability.

Advantages:

Larger capacity than both 18650 and 21700 batteries.

Excellent performance under high-rate discharge conditions.

Long lifespan, reducing replacement frequency in industrial systems.

Disadvantages:

Bulky size, which may not fit compact devices.

Requires advanced thermal management to maintain efficiency.

Use Cases:

You’ll often see 26650 batteries in unmanned ground vehicle (UGV) and commercial tools. Their high capacity and durability make them suitable for demanding industrial environments.

3.4 Practical Insights for Industrial Applications

Choosing the right cylindrical lithium-ion battery size depends on your specific industrial needs. For instance, if your application prioritizes compact designs, the 18650 battery offers a cost-effective solution. However, for systems requiring higher capacity and energy density, the 21700 or 26650 batteries provide superior performance.

A study on lithium-ion battery design highlights the importance of optimizing configurations for recycling efficiency and lifecycle cost reduction. Designs like CTP (cell-to-pack) and CTB (cell-to-battery) outperform traditional setups in recyclability and cost-effectiveness. These insights emphasize the need for strategic battery selection to enhance operational efficiency and sustainability.

Understanding different battery sizes is essential for optimizing industrial and commercial applications. Each size offers unique advantages, from the cost-efficiency of 18650 batteries to the high capacity of 26650 cells. Key factors like energy density, compatibility, and cost significantly influence battery selection:

The 18650 battery provides the best cost-to-energy ratio, making it ideal for mobile computing.

Prismatic cells suit slim designs but involve higher costs.

Energy consumption for producing lithium-ion cells varies between 30 and 55 kWh per kWh, highlighting the importance of cost considerations.

Evaluating your specific requirements ensures the right battery size for your application. For example, automotive OEMs develop test protocols to assess battery performance, while aerospace clients evaluate thermal and electric management systems. Consulting Large Power helps you navigate these complexities and achieve optimal battery pack solutions.

FAQ

1. How do I choose the best lithium-ion battery size for my industrial application?

Evaluate your energy density, voltage, and capacity needs. For expert guidance, consult trusted providers like Large Power to optimize your battery pack design.

2. What is the difference between NCM, LCO, and LiFePO4 batteries?

NCM offers 160–270 Wh/kg and 1,000–2,000 cycles. LCO provides 180–230 Wh/kg but shorter lifespans. LiFePO4 prioritizes durability with 2,000–5,000 cycles and 100–180 Wh/kg.

Tip: For long-lasting industrial systems, LiFePO4 batteries are often the most reliable choice.

3. How can I ensure my battery pack meets safety standards?

Incorporate a Battery Management System (BMS) to monitor voltage and temperature. Partnering with experts like Large Power ensures compliance with industrial safety protocols.